Nkọwa Ngwaahịa

Ozi Ọkọlọtọ - ASME/ANSI B16.5 na B16.47 - Flanges Paịpụ na ihe ndị e ji akpụ akpụ

Ọkọlọtọ ASME B16.5 na-ekpuchi akụkụ dị iche iche nke flanges paịpụ na ihe ndị e ji agbaze agbaze, gụnyere ọkwa okpomọkụ nrụgide, ihe, nha, ndidi, akara, nnwale, na ịkọwapụta oghere maka ihe ndị a. Ọkọlọtọ a gụnyere flanges nwere aha ọkwa dị site na 150 ruo 2500, na-ekpuchi nha site na NPS 1/2 ruo NPS 24. Ọ na-enye ihe achọrọ na ma nkeji metric na nke US. Ọ dị mkpa ịmara na ọkọlọtọ a bụ naanị flanges na ihe ndị e ji agbaze agbaze eme nke e ji ihe e ji agbaze agbaze eme, gụnyere flanges kpuru ìsì na flanges ndị a na-ebelata nke e ji ihe e ji agbaze agbaze eme, ihe e ji agbaze agbaze eme, ma ọ bụ ihe e ji efere mee.

Maka flanges paịpụ na ihe ndị e ji agbaze agba nke karịrị NPS 24", a ga-atụle ASME/ANSI B16.47.

Ụdị Flange Ndị A Na-ahụkarị

● Flanges Slip-On: A na-etinye flanges ndị a n'ime ANSI Klas 150, 300, 600, 1500 na 2500 ruo 24" NPS. A na-amịpụ ha n'elu paịpụ ma ọ bụ nsọtụ ihe ndị dabara adaba ma jikọta ha n'ọnọdụ ha, na-enye ohere maka ịgbado fillet ma n'ime ma n'èzí flange. A na-eji ụdị mbelata iji belata nha ahịrị mgbe oghere pere mpe.

● Flanges Olu Njikọta: Flanges ndị a nwere etiti dị ogologo nke na-agbanwe agbanwe nke ọma na mgbanwe dị nro nke ọkpụrụkpụ, na-eme ka njikọ njikọta njikọta zuru oke na paịpụ ma ọ bụ ihe e ji etinye ya. A na-eji ha eme ihe n'ọnọdụ ọrụ siri ike.

● Njikọta Lap: A na-ejikọta flanges njikọ lap eme ihe, a na-amịpụkwa flanges njikọ lap n'elu ihe e ji etinye stub wee jikọta ha site na iji njikọ ma ọ bụ ụzọ ndị ọzọ. Nhazi ha na-adịghị mma na-enye ohere maka nhazi dị mfe n'oge njikọta na mwepụ.

● Flanges Azụ: Flanges ndị a enweghị ihu elu ma ejiri ha na mgbaaka nkwado, na-enye ngwọta dị ọnụ ala maka njikọ flanges.

● Flanges E tinyere n'ime eriri (Kpọrọ): Ebe ọ bụ na ike gwụrụ ya ka ọ dabara na dayameta dị n'ime eriri, a na-eji eriri paịpụ e ji eriri kpuchie ya n'akụkụ azụ, karịsịa maka obere paịpụ oghere.

● Mgbawa Njikọta Socket Weld: A na-eji ígwè dịka flanges slip-on, socket weld flanges eme ihe ka ha kwekọọ na oghere paịpụ nha, na-enye ohere ka e jiri fillet connection mee ihe n'azụ iji jide njikọ ahụ. A na-ejikarị ha eme obere ọkpọkọ oghere.

● Flanges ndị a na-enweghị oghere etiti ma a na-eji ha emechi ma ọ bụ gbochie njedebe nke sistemụ paịpụ.

Ndị a bụ ụfọdụ ụdị flanges paịpụ a na-ejikarị eme ihe n'ọtụtụ ọrụ ụlọ ọrụ na azụmaahịa. Nhọrọ nke ụdị flanges dabere na ihe dịka nrụgide, okpomọkụ, na ụdị mmiri a na-ebuga, yana ihe achọrọ maka ọrụ. Nhọrọ na ntinye nke flanges kwesịrị ekwesị dị oke mkpa maka ọrụ nchekwa na nke dị irè nke sistemụ paịpụ.

Nkọwapụta

| ASME B16.5: Ígwè Carbon, Ígwè anaghị agba nchara, Ígwè Alloy |

| EN 1092-1: Ígwè Carbon, Ígwè anaghị agba nchara, Ígwè Alloy |

| DIN 2501: Ígwè Carbon, Ígwè anaghị agba nchara, Ígwè Alloy |

| GOST 33259: Ígwè Carbon, Ígwè anaghị agba nchara, Ígwè Alloy |

| SABS 1123: Ígwè Carbon, Ígwè anaghị agba nchara, Ígwè Alloy |

Ihe Flange

A na-ejikọta flanges na paịpụ na ihe eji arụ ọrụ. N'ihi ya, a na-eji ihe ndị a emepụta ya;

● Ígwè carbon

● Ígwè alloy dị ala

● Ígwè anaghị agba nchara

● Njikọta nke ihe ndị ọzọ dị iche iche (Stub) na ihe ndị ọzọ na-akwado ya

Ndepụta ihe eji eme ihe n'ime mmepụta ihe dị na ASME B16.5 na B16.47.

● ASME B16.5 -Ọkpọkọ ọkpọkọ na ihe ndị e ji mee ya NPS ½" ruo 24"

● ASME B16.47 - NPS 26" ruo 60" nke nwere dayameta buru ibu

A na-ejikarị ihe ndị e ji emepụta ihe eme ihe

● Ígwè Carbon: – ASTM A105, ASTM A350 LF1/2, ASTM A181

● Ígwè Alloy: – ASTM A182F1 /F2 /F5 /F7 /F9 /F11 /F12 /F22

● Ígwè anaghị agba nchara: – ASTM A182F6 /F304 /F304L /F316 /F316L/ F321/F347/F348

Akụkụ Flange 150 nke Klas 150

| Nha na Inchi | Nha na mm | Dia Mpụta. | Flange dị arọ. | Ebe etiti OD | Ogologo Flange | RF Dia. | Ogologo RF | PCD | Oghere Socket | Ọnụọgụ nke Bọltị | Nha Bọltị UNC | Ogologo Igwe Bọltị | Ogologo Stud RF | Nha oghere | Nha Ọkpụkpọ ISO | Ibu na kg |

|

|

| A | B | C | D | E | F | G | H |

|

|

|

|

|

|

|

| 1/2 | 15 | 90 | 9.6 | 30 | 14 | 34.9 | 2 | 60.3 | 22.2 | 4 | 1/2 | 50 | 55 | 5/8 | M14 | 0.8 |

| 3/4 | 20 | 100 | 11.2 | 38 | 14 | 42.9 | 2 | 69.9 | 27.7 | 4 | 1/2 | 50 | 65 | 5/8 | M14 | 0.9 |

| 1 | 25 | 110 | 12.7 | 49 | 16 | 50.8 | 2 | 79.4 | 34.5 | 4 | 1/2 | 55 | 65 | 5/8 | M14 | 0.9 |

| 1 1/4 | 32 | 115 | 14.3 | 59 | 19 | 63.5 | 2 | 88.9 | 43.2 | 4 | 1/2 | 55 | 70 | 5/8 | M14 | 1.4 |

| 1 1/2 | 40 | 125 | 15.9 | 65 | 21 | 73 | 2 | 98.4 | 49.5 | 4 | 1/2 | 65 | 70 | 5/8 | M14 | 1.4 |

| 2 | 50 | 150 | 17.5 | 78 | 24 | 92.1 | 2 | 120.7 | 61.9 | 4 | 5/8 | 70 | 85 | 3/4 | M16 | 2.3 |

| 2 1/2 | 65 | 180 | 20.7 | 90 | 27 | 104.8 | 2 | 139.7 | 74.6 | 4 | 5/8 | 75 | 90 | 3/4 | M16 | 3.2 |

| 3 | 80 | 190 | 22.3 | 108 | 29 | 127 | 2 | 152.4 | 90.7 | 4 | 5/8 | 75 | 90 | 3/4 | M16 | 3.7 |

| 3 1/2 | 90 | 215 | 22.3 | 122 | 30 | 139.7 | 2 | 177.8 | 103.4 | 8 | 5/8 | 75 | 90 | 3/4 | M16 | 5 |

| 4 | 100 | 230 | 22.3 | 135 | 32 | 157.2 | 2 | 190.5 | 116.1 | 8 | 5/8 | 75 | 90 | 3/4 | M16 | 5.9 |

| 5 | 125 | 255 | 22.3 | 164 | 35 | 185.7 | 2 | 215.9 | 143.8 | 8 | 3/4 | 85 | 95 | 7/8 | M20 | 6.8 |

| 6 | 150 | 280 | 23.9 | 192 | 38 | 215.9 | 2 | 241.3 | 170.7 | 8 | 3/4 | 85 | 100 | 7/8 | M20 | 8.6 |

| 8 | 200 | 345 | 27 | 246 | 43 | 269.9 | 2 | 298.5 | 221.5 | 8 | 3/4 | 90 | 110 | 7/8 | M20 | 13.7 |

| 10 | 250 | 405 | 28.6 | 305 | 48 | 323.8 | 2 | 362 | 276.2 | 12 | 7/8 | 100 | 115 | 1 | M24 | 19.5 |

| 12 | 300 | 485 | 30.2 | 365 | 54 | 381 | 2 | 431.8 | 327 | 12 | 7/8 | 100 | 120 | 1 | M24 | 29 |

| 14 | 350 | 535 | 33.4 | narị anọ | 56 | 412.8 | 2 | 476.3 | 359.2 | 12 | 1 | 115 | 135 | 1 1/8 | M27 | 41 |

| 16 | narị anọ | 595 | 35 | 457 | 62 | 469.9 | 2 | 539.8 | 410.5 | 16 | 1 | 115 | 135 | 1 1/8 | M27 | 54 |

| 18 | 450 | 635 | 38.1 | 505 | 67 | 533.4 | 2 | 577.9 | 461.8 | 16 | 1 1/8 | 125 | 145 | 1 1/4 | M30 | 59 |

| 20 | 500 | 700 | 41.3 | 559 | 71 | 584.2 | 2 | 635 | 513.1 | 20 | 1 1/8 | 140 | 160 | 1 1/4 | M30 | 75 |

| 24 | narị isii | 815 | 46.1 | 663 | 81 | 692.2 | 2 | 749.3 | 616 | 20 | 1 1/4 | 150 | 170 | 1 3/8 | M33 | 100 |

Nha Flange Olu nke Klas 150 Weld

| Nha na Inchi | Nha na mm | Dayameta Mpụta | Ọkpụrụkpụ nke Flange | Ebe etiti OD | Olu Weld OD | Ogologo Olu Ịgbado Ọkụ | Oghere | Dayameta RF | Ogologo RF | PCD | Ihu Weld |

|

|

| A | B | C | D | E | F | G | H | I | J |

| 1/2 | 15 | 90 | 9.6 | 30 | 21.3 | 46 | A na-esi na usoro paịpụ agbado ọkụ | 34.9 | 2 | 60.3 | 1.6 |

| 3/4 | 20 | 100 | 11.2 | 38 | 26.7 | 51 | 42.9 | 2 | 69.9 | 1.6 | |

| 1 | 25 | 110 | 12.7 | 49 | 33.4 | 54 | 50.8 | 2 | 79.4 | 1.6 | |

| 1 1/4 | 32 | 115 | 14.3 | 59 | 42.2 | 56 | 63.5 | 2 | 88.9 | 1.6 | |

| 1 1/2 | 40 | 125 | 15.9 | 65 | 48.3 | 60 | 73 | 2 | 98.4 | 1.6 | |

| 2 | 50 | 150 | 17.5 | 78 | 60.3 | 62 | 92.1 | 2 | 120.7 | 1.6 | |

| 2 1/2 | 65 | 180 | 20.7 | 90 | 73 | 68 | 104.8 | 2 | 139.7 | 1.6 | |

| 3 | 80 | 190 | 22.3 | 108 | 88.9 | 68 | 127 | 2 | 152.4 | 1.6 | |

| 3 1/2 | 90 | 215 | 22.3 | 122 | 101.6 | 70 | 139.7 | 2 | 177.8 | 1.6 | |

| 4 | 100 | 230 | 22.3 | 135 | 114.3 | 75 | 157.2 | 2 | 190.5 | 1.6 | |

| 5 | 125 | 255 | 22.3 | 164 | 141.3 | 87 | 185.7 | 2 | 215.9 | 1.6 | |

| 6 | 150 | 280 | 23.9 | 192 | 168.3 | 87 | 215.9 | 2 | 241.3 | 1.6 | |

| 8 | 200 | 345 | 27 | 246 | 219.1 | 100 | 269.9 | 2 | 298.5 | 1.6 | |

| 10 | 250 | 405 | 28.6 | 305 | 273 | 100 | 323.8 | 2 | 362 | 1.6 | |

| 12 | 300 | 485 | 30.2 | 365 | 323.8 | 113 | 381 | 2 | 431.8 | 1.6 | |

| 14 | 350 | 535 | 33.4 | narị anọ | 355.6 | 125 | 412.8 | 2 | 476.3 | 1.6 | |

| 16 | narị anọ | 595 | 35 | 457 | 406.4 | 125 | 469.9 | 2 | 539.8 | 1.6 | |

| 18 | 450 | 635 | 38.1 | 505 | 457.2 | 138 | 533.4 | 2 | 577.9 | 1.6 | |

| 20 | 500 | 700 | 41.3 | 559 | 508 | 143 | 584.2 | 2 | 635 | 1.6 | |

| 24 | narị isii | 815 | 46.1 | 663 | 610 | 151 | 692.2 | 2 | 749.3 | 1.6 |

Nha nke Flange Blind Klas 150

| Nha | Nha | Mpụta | Flange | RF | RF | PCD | Ọnụọgụgụ nke | Nha Bọltị | Igwe mkpọchi | RF Stud | Nha oghere | ISO Stud | Ibu |

| A | B | C | D | E | |||||||||

| 1/2 | 15 | 90 | 9.6 | 34.9 | 2 | 60.3 | 4 | 1/2 | 50 | 55 | 5/8 | M14 | 0.9 |

| 3/4 | 20 | 100 | 11.2 | 42.9 | 2 | 69.9 | 4 | 1/2 | 50 | 65 | 5/8 | M14 | 0.9 |

| 1 | 25 | 110 | 12.7 | 50.8 | 2 | 79.4 | 4 | 1/2 | 55 | 65 | 5/8 | M14 | 0.9 |

| 1 1/4 | 32 | 115 | 14.3 | 63.5 | 2 | 88.9 | 4 | 1/2 | 55 | 70 | 5/8 | M14 | 1.4 |

| 1 1/2 | 40 | 125 | 15.9 | 73 | 2 | 98.4 | 4 | 1/2 | 65 | 70 | 5/8 | M14 | 1.8 |

| 2 | 50 | 150 | 17.5 | 92.1 | 2 | 120.7 | 4 | 5/8 | 70 | 85 | 3/4 | M16 | 2.3 |

| 2 1/2 | 65 | 180 | 20.7 | 104.8 | 2 | 139.7 | 4 | 5/8 | 75 | 90 | 3/4 | M16 | 3.2 |

| 3 | 80 | 190 | 22.3 | 127 | 2 | 152.4 | 4 | 5/8 | 75 | 90 | 3/4 | M16 | 4.1 |

| 3 1/2 | 90 | 215 | 22.3 | 139.7 | 2 | 177.8 | 8 | 5/8 | 75 | 90 | 3/4 | M16 | 5.9 |

| 4 | 100 | 230 | 22.3 | 157.2 | 2 | 190.5 | 8 | 5/8 | 75 | 90 | 3/4 | M16 | 7.7 |

| 5 | 125 | 255 | 22.3 | 185.7 | 2 | 215.9 | 8 | 3/4 | 85 | 95 | 7/8 | M20 | 9.1 |

| 6 | 150 | 280 | 23.9 | 215.9 | 2 | 241.3 | 8 | 3/4 | 85 | 100 | 7/8 | M20 | 11.8 |

| 8 | 200 | 345 | 27 | 269.9 | 2 | 298.5 | 8 | 3/4 | 90 | 110 | 7/8 | M20 | 20.5 |

| 10 | 250 | 405 | 28.6 | 323.8 | 2 | 362 | 12 | 7/8 | 100 | 115 | 1 | M24 | 32 |

| 12 | 300 | 485 | 30.2 | 381 | 2 | 431.8 | 12 | 7/8 | 100 | 120 | 1 | M24 | 50 |

| 14 | 350 | 535 | 33.4 | 412.8 | 2 | 476.3 | 12 | 1 | 115 | 135 | 1 1/8 | M27 | 64 |

| 16 | narị anọ | 595 | 35 | 469.9 | 2 | 539.8 | 16 | 1 | 115 | 135 | 1 1/8 | M27 | 82 |

| 18 | 450 | 635 | 38.1 | 533.4 | 2 | 577.9 | 16 | 1 1/8 | 125 | 145 | 1 1/4 | M30 | 100 |

| 20 | 500 | 700 | 41.3 | 584.2 | 2 | 635 | 20 | 1 1/8 | 140 | 160 | 1 1/4 | M30 | 130 |

| 24 | narị isii | 815 | 46.1 | 692.2 | 2 | 749.3 | 20 | 1 1/4 | 150 | 170 | 1 3/8 | M33 | 196 |

Ọkọlọtọ na ọkwa

| ASME B16.5: Flanges Paịpụ na ihe ndị e ji ekpuchi oghere | Ihe ndị e ji mee ihe: Ígwè Carbon, Ígwè anaghị agba nchara, Ígwè Alloy |

| EN 1092-1: Flanges na njikọ ha - Flanges okirikiri maka ọkpọkọ, valvụ, ihe ndị e ji etinye ihe, na ngwa, PN A họpụtara - Nkebi nke 1: Flanges ígwè | Ihe ndị e ji mee ihe: Ígwè Carbon, Ígwè anaghị agba nchara, Ígwè Alloy

|

| DIN 2501: Flanges na nkwonkwo ndị a gbajiri agbaji | Ihe ndị e ji mee ihe: Ígwè Carbon, Ígwè anaghị agba nchara, Ígwè Alloy |

| GOST 33259: Flanges maka valvụ, ihe ndị e ji etinye ihe, na ọkpọkọ maka nrụgide ruo PN 250 | Ihe ndị e ji mee ihe: Ígwè Carbon, Ígwè anaghị agba nchara, Ígwè Alloy |

| SABS 1123: Flanges maka Paịpụ, Valvụ, na ihe ndị e ji etinye ya | Ihe ndị e ji mee ihe: Ígwè Carbon, Ígwè anaghị agba nchara, Ígwè Alloy |

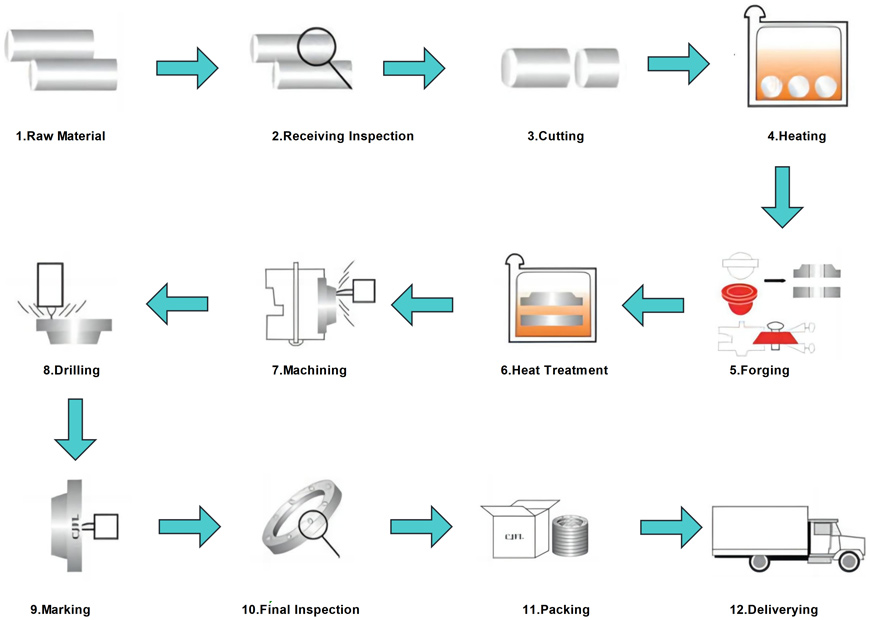

Usoro Mmepụta

Njikwa Ogo

Nnyocha Ihe Ndị Dị n'ime, Nnyocha Kemịkalụ, Nnwale Mekanik, Nnyocha Anya, Nlele Nha, Nnwale Gbagọrọ Agbagọ, Nnwale Dị larịị, Nnwale Mmetụta, Nnwale DWT, Nnwale Na-anaghị Ebibi (UT, MT, PT, X-Ray,), Nnwale Ike, Nnwale Nrụgide, Nnwale Ntapụ Oche, Nnwale Metallography, Nnwale Ntapụ, Nnwale Ntapụ Ọkụ, Nnwale Ntapụ Nnu, Nnwale Arụmọrụ Mmiri, Nnwale Torque na Thrust, Agba na Mkpuchi, Nyocha Akwụkwọ....

Ojiji na Ngwa

Flanges bụ akụkụ dị mkpa nke ụlọ ọrụ mmepụta ihe eji ejikọ paịpụ, valvụ, akụrụngwa na akụkụ paịpụ ndị ọzọ. Ha na-arụ ọrụ dị mkpa n'ịjikọta, ịkwado na ikpuchi sistemụ paịpụ. Flanges na-arụ ọrụ dị ka ihe dị mkpa na ngwa ụlọ ọrụ dị iche iche, gụnyere:

● Sistemụ Paịpụ

● Valvụ

● Ngwaọrụ

● Njikọ

● Ịmechi ihe

● Njikwa Nrụgide

Nkwakọ ngwaahịa na Mbupu

Na Womic Steel, anyị ghọtara mkpa ọ dị nkwakọ ngwaahịa dị mma na mbupu a pụrụ ịtụkwasị obi ma a bịa n'ibuga ihe ndị dị mkpa anyị nwere na paịpụ n'ọnụ ụzọ gị. Lee nkọwa zuru ezu nke usoro nkwakọ ngwaahịa na mbupu anyị maka ntụaka gị:

Nkwakọ ngwaahịa:

A na-eji nlezianya ekpuchi flanges paịpụ anyị iji hụ na ha ruru gị n'ọnọdụ zuru oke, dị njikere maka mkpa ụlọ ọrụ ma ọ bụ azụmahịa gị. Usoro nkwakọ ngwaahịa anyị gụnyere usoro ndị a dị mkpa:

● Nnyocha Ogo: Tupu e tinye ihe mkpuchi, a na-enyocha flanges niile nke ọma iji hụ na ha na-emezu ụkpụrụ siri ike anyị maka arụmọrụ na iguzosi ike n'ezi ihe.

● Mkpuchi Nchedo: Dabere n'ụdị ihe na ojiji ya, flanges anyị nwere ike ịnweta mkpuchi nchebe iji gbochie nchara na mmebi n'oge njem.

● Njikọta Nchekwa: A na-ejikọta flanges ọnụ nke ọma, na-eme ka ha guzosie ike ma nwee nchebe n'oge usoro mbupu.

● Ịdepụta akara na akwụkwọ: E tinyere ozi dị mkpa n'ime ngwugwu ọ bụla n'ụzọ doro anya, gụnyere nkọwapụta ngwaahịa, ọnụọgụgụ, na ntuziaka njikwa pụrụ iche ọ bụla. Akwụkwọ ndị dị mkpa, dị ka asambodo nke nrubeisi, tinyekwara.

● Nkwakọ ngwaahịa ahaziri ahazi: Anyị nwere ike ịnabata arịrịọ nkwakọ ngwaahịa pụrụ iche dabere na ihe pụrụ iche ị chọrọ, na-ahụ na edoziri flanges gị kpọmkwem dịka ọ dị mkpa.

Mbupu:

Anyị na ndị mmekọ mbupu a ma ama na-arụkọ ọrụ iji hụ na nnyefe a pụrụ ịtụkwasị obi na nke oge ruru ebe ị na-aga. Ndị otu njem anyị na-ahazi ụzọ mbupu iji belata oge njem ma belata ihe egwu nke igbu oge. Maka mbupu mba ofesi, anyị na-ejikwa akwụkwọ omenala niile dị mkpa na nrubeisi iji mee ka mwepụta omenala dị mfe. Anyị na-enye nhọrọ mbupu na-agbanwe agbanwe, gụnyere mbupu ngwa ngwa maka ihe achọrọ ngwa ngwa.