1. Nchịkọta Ihe

Paịpụ ígwè anaghị agba nchara 347H bụ ígwè austenitic nke nwere carbon niobium siri ike nke a maara maka ike dị elu ya, ike ịgbado ọkụ nke ọma, na iguzogide nchara dị n'etiti granular. Mgbakwunye nke niobium (Nb) na-eme ka ike ịrị elu dịkwuo mma ma na-egbochi mmiri ozuzo chromium carbide n'akụkụ ókèala ọka, na-eme ka iguzogide mmetụta dịkwuo mma.

2.Ihe mejupụtara kemịkalụ (Nkịtị)

| Ihe | Ọdịnaya (%) |

| C | 0.04 – 0.10 |

| Cr | 17.0 – 19.0 |

| Ni | 9.0 – 13.0 |

| Si | ≤1.0 |

| Mn | ≤ 2.00 |

| P | ≤ 0.045 |

| S | ≤ 0.030 |

3. Njirimara Mechanical & Corrosion

Njirimara Mekaniki (ASTM A213):

- Ike nrụgide ≥ 515 MPa

- Ike Mmepụta ≥ 205 MPa

- Ogologo oge ≥ 35%

- Ike mgbawa na-agbawa agbawa na 600°C: >100 MPa

Nguzogide Nrụrụ:

- Ezigbo nguzogide nchara dị n'etiti granular n'ihi nkwụsi ike Nb

- Nguzogide dị mma na nitric acid, acetic acid, gburugburu alkaline, na mmiri mmiri

- A nwalere ya maka ire ere nnu gbazere agbaze, a nwalekwara arụmọrụ ya na tankị nchekwa nnu CSP gbazere agbaze

- Ọ na-enwe mmetụta dị ntakịrị karịa 316L maka olulu mmiri chloride kpatara, nke a na-ebelata site na passivation na ọgwụgwọ elu.

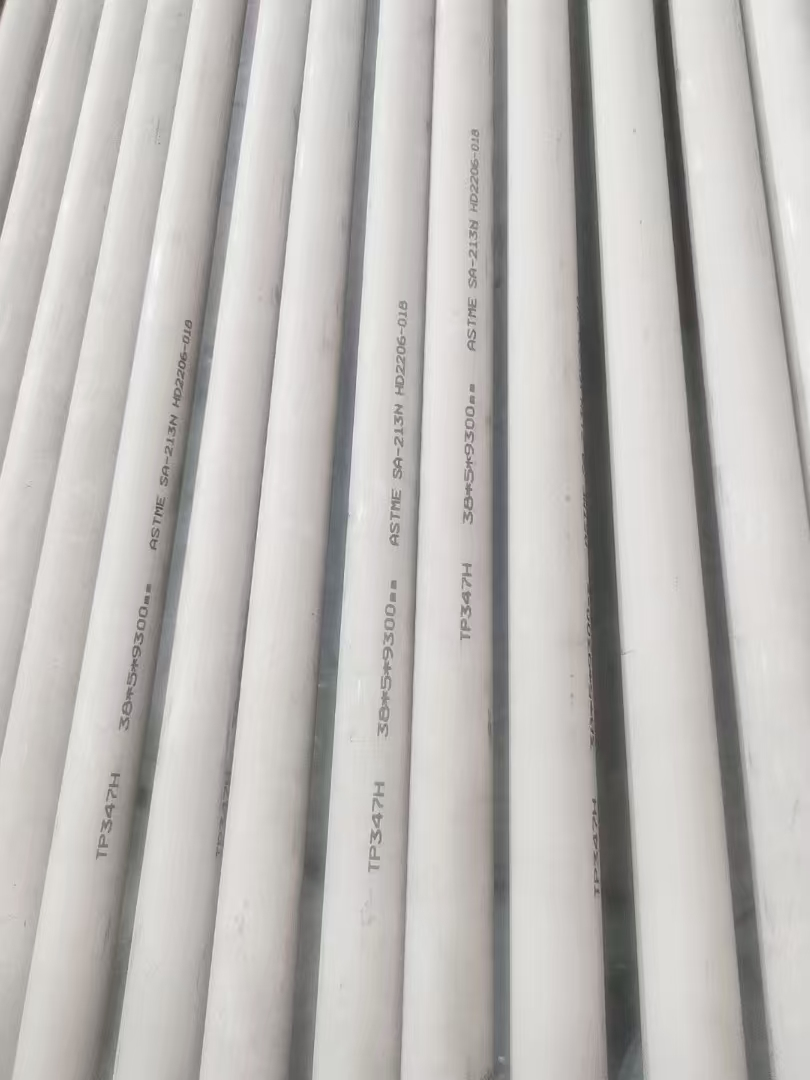

4. Nkọwapụta Ngwaahịa A Na-ahụkarị

Akụkụ:

- Paịpụ Na-enweghị Ntụpọ: OD 1/4”–36”, ọkpụrụkpụ mgbidi SCH10–SCH160

- Tubes nke a kapịrị ọnụ: OD 10mm–108mm, nke a na-ese n'oyi

- Paịpụ e ji agbakọta: Paịpụ mgbidi dị gịrịgịrị ruo n'okpukpu site na iji TIG, PAW, na SAW welding

- Ogologo: Ruo mita 12; ogologo ịkpụzi omenala dị

Ụkpụrụ Mmepụta:

- ASTM A213/A312, ASME SA213/SA312

- EN 10216-5, GB/T 5310

- Ndabere na arịa nrụgide: PED, AD2000 W0, Koodu ASME Nkebi nke VIII Nkebi nke 1

5. Usoro Mmepụta

1. Ihe Ndị A Na-anaghị Ewu: E ji ígwè eme ihe nke ọma site n'aka ụlọ ọrụ mmepụta ihe nke mba na nke ụwa.

2. Mkpọgharị Na-ekpo Ọkụ: A na-ekpo ọkụ na Billets ruo 1150–1200°C, a na-apịa ha ma na-atụgharị ha maka nnukwu dayameta ma ọ bụ ọkpọkọ mgbidi dị arọ.

3. Ihe osise oyi: Ihe osise oyi na-agafe ọtụtụ ugboro maka nha ziri ezi na imecha elu

4. Ọgwụgwọ Okpomọkụ: Ịkwụsị mmiri ọkụ na 980–1150°C, ime ka mmiri dị ngwa ngwa kwụsị mmiri ozuzo carbide

5. Ịgbado ọkụ: Usoro GTAW (TIG), PAW, na SAW, site na iji waya ihe eji eme ka ihe sie ike; nhọrọ nhicha azụ dị

6. Mmecha Elu: Ịpịcha ihe, passivation (HNO₃/HF), na ime ka ihe dị ọcha n'ime igwe (Ra ≤ 0.2µm ma ọ bụrụ na achọrọ ya)

7. Nnyocha: 100% RT (nnwale redio) maka ịgbado ọkụ; ultrasonic, hydrostatic, PMI, nnwale corrosion dị n'etiti granular dịka ọ dị mkpa

6. Asambodo na Njikwa Ogo

Paịpụ ígwè anaghị agba nchara nke Womic Steel 347H nwere asambodo:

- ISO 9001: 2015

- PED 2014/68/EU

- AD2000 W0

- Koodu ụgbọ mmiri ASME na nke nrụgide

A na-anwale otu ọ bụla nke ọma, gụnyere:

- Nnwale igwe (nrụgide, mmetụta, ịcha mma, ịgba ọkụ)

- Nnwale ire ere (IGC kwa ASTM A262)

- Nnwale na-anaghị emebi emebi (UT, RT, Eddy current)

- Nnyocha nha na nleba anya zuru oke

7. Ubi Ngwa

A na-ejikarị ọkpọkọ ígwè anaghị agba nchara 347H eme ihe n'ọtụtụ ebe:

- Mmepụta Ike: Igwe ọkụ dị elu, igwe na-ekpo ọkụ, ọkpọkọ uzuoku bụ isi na osisi ike dị oke mkpa na nke dị oke mkpa

- Ike Okpomọkụ nke Anyanwụ: Tankị nchekwa ọkụ nnu a kpụrụ akpụ (450–565°C), ejiri ya rụọ ọrụ n'ofe China (Yumen, Haixi)

- Petrochemical: Ọkụ ọkụ, ihe ndị na-eme ka mmiri na-arụ ọrụ (na-eguzogide gburugburu H₂-H₂S-H₂O)

- Ụgbọelu: Ọwara ikuku nke injin na ọkpọkọ ikuku turbine (na-arụ ọrụ ruo 850°C)

- Ihe Mgbanwe Okpomọkụ: Ihe ndị na-eme ka okpomọkụ dị elu na ọkpọkọ dị na ụlọ ọrụ mmepụta ihe na sistemụ mmiri

8. Oge Mmepụta

- Tubes Na-enweghị Nsogbu (Nha Ọkọlọtọ): ụbọchị 15–25

- Nha Pụrụ Iche/Ọkpọ Mgbidi Dị Oke: ụbọchị 30–45

- Iwu buru ibu: Ike karịrị tọn 3,000 kwa ọnwa na-eme ka nnyefe ngwa ngwa ọbụlagodi n'oge dị mkpa

9. Nkwakọ ngwaahịa na nhazi

Womic Steel na-enye nkwakọ ngwaahịa dị nchebe ma nwee ike ịhazi ya:

- Igbe Osisi ma ọ bụ Ngwugwu Etiti Efere nke Dị Oké Osimiri

- Mkpuchi njedebe plastik, mmanụ mgbochi nchara, na ihe mkpuchi fim

- Nkwakọ ngwaahịa mbupụ niile kwekọrọ na ụkpụrụ ISPM-15

Uru Njem:

- Ọnụego CIF/CFR asọmpi

- Nbufe ngwa ngwa site n'ọdụ ụgbọ mmiri ruo n'ọnụ ụzọ gaa Ndịda Ọwụwa Anyanwụ Eshia, India, Europe, na Middle East

- Ibu ibu siri ike maka mgbochi ịgbagọ agbagọ, mgbochi mmịpụ, na mgbochi nkukota n'oge mbupu

10. Ọrụ Nhazi

- Ịgbagọ (oyi na ọkụ na-akpụ)

- Ịchacha nkenke

- Ịmecha eriri na njedebe

- Mgbakọ ịgbado ọkụ (spools na ikpere aka)

- Nhazi omenala maka eserese ọ bụla

11. Gịnị mere ị ga-eji họrọ Womic Steel?

- Ụlọ nyocha R&D na QA n'ime ụlọ

- Usoro ọkọnọ siri ike nke ihe eji emepụta ihe na-eme ka usoro nnyefe dị mkpụmkpụ

- Ọtụtụ iri afọ nke ahụmịhe ígwè, ọkachasị na alloys dị elu

- Nchọta zuru oke na akwụkwọ maka nnabata akụrụngwa nrụgide

- Onye na-enye ngwọta otu nkwụsị maka ịzụta, nhazi, na mbupụ sistemụ ọkpọkọ ígwè anaghị agba nchara

Maka mpempe akwụkwọ data teknụzụ, ọnụahịa, na ọnụahịa ọrụ ahaziri iche, kpọtụrụ Womic Steel taa. Anyị dị njikere ịkwado mkpa ọkpọkọ gị dị elu site na nkenke, ọsọ, na iguzosi ike n'ezi ihe.

Họrọ Womic Steel Group dị ka onye mmekọ gị a pụrụ ịtụkwasị obi makaTubes ígwè anaghị agba ncharana arụmọrụ nnyefe a na-apụghị imeri emeri. Nnọọ na ajụjụ!

Weebụsaịtị: www.womicsteel.com

ozi-e: sales@womicsteel.com

Ekwentị/WhatsApp/WeChat: Victor: +86-15575100681 ma ọ bụ Jack: +86-18390957568

Oge ozi: Eprel-16-2025