Ọgwụgwọ okpomọkụ na-ezo aka na usoro okpomọkụ ígwè nke a na-ekpo ọkụ, jide ma jụọ oyi site na iji kpo oku n'ọnọdụ siri ike iji nweta nhazi na ihe onwunwe achọrọ.

I. Ọgwụgwọ Okpomọkụ

1, Nhazi: iberibe ígwè ma ọ bụ ígwè a na-ekpo ọkụ ruo ebe dị mkpa nke AC3 ma ọ bụ ACM karịa okpomọkụ kwesịrị ekwesị iji nọgide na-enwe oge ụfọdụ mgbe ọ jụrụ oyi n'ikuku, iji nweta ụdị nhazi nke usoro ọgwụgwọ okpomọkụ.

2, Mgbakwunye: Eutectic workpiece eutectic workpiece a na-ekpo ọkụ ruo AC3 karịa ogo 20-40, mgbe ejiri ya ruo oge ụfọdụ, na-eme ka ọkụ ahụ dị jụụ nwayọ nwayọ (ma ọ bụ lie ya n'ájá ma ọ bụ lime oyi) ruo ogo 500 n'okpuru oyi na usoro ọgwụgwọ okpomọkụ ikuku.

3, Ngwọta Okpomọkụ siri ike: a na-ekpo ọkụ alloy ahụ ruo n'ókè okpomọkụ dị elu nke otu usoro okpomọkụ na-adịgide adịgide iji nọgide na-enwe, nke mere na usoro ngafe ahụ na-agbaze kpamkpam ka ọ bụrụ ngwọta siri ike, wee jụọ oyi ngwa ngwa iji nweta usoro ọgwụgwọ okpomọkụ siri ike nke zuru oke.

4, Ịka nká: Mgbe ngwọta siri ike ọgwụgwọ okpomọkụ ma ọ bụ mgbanwe plastik oyi nke alloy ahụ, mgbe a na-etinye ya na okpomọkụ ụlọ ma ọ bụ na-edebe ya na okpomọkụ dị elu karịa okpomọkụ ụlọ, ihe omume nke ihe onwunwe ya na-agbanwe ka oge na-aga.

5, Ọgwụgwọ ngwọta siri ike: ka alloy ahụ wee gbazee nke ọma n'ọtụtụ usoro, mee ka ngwọta siri ike sie ike ma melite ike na iguzogide nchara, wepụ nrụgide na nro, iji nọgide na-akpụzi ihe.

6, Ọgwụgwọ Ịka nká: ikpo ọkụ na ijide n'okpomọkụ nke mmiri ozuzo nke usoro nkwado, ka mmiri ozuzo nke usoro nkwado wee daa, mee ka ọ sie ike, iji melite ike.

7, Ịgbanyụ: ịgbanyụ ígwè mgbe ọ jụrụ oyi na ọnụego oyi kwesịrị ekwesị, nke mere na ọrụ ahụ dị n'akụkụ nke ihe niile ma ọ bụ ụfọdụ usoro nhazi na-adịghị akwụsi ike dịka mgbanwe martensite nke usoro ọgwụgwọ okpomọkụ.

8, Ọkụ: a ga-ekpo ọkụ ihe eji emenyụ ọkụ ahụ ruo ebe dị mkpa nke AC1 n'okpuru okpomọkụ kwesịrị ekwesị maka oge ụfọdụ, wee jụọ oyi dịka usoro ahụ si dị, iji nweta nhazi na njirimara nke usoro ọgwụgwọ okpomọkụ achọrọ.

9, Ịnya ígwè: Ịnya ígwè na-abanye n'elu ígwè n'otu oge ahụ ịbanye n'ime usoro carbon na nitrogen. A makwaara carbonitriding omenala dị ka cyanide, carbonitriding gas dị n'etiti okpomọkụ na obere okpomọkụ carbonitriding (dịka ọmụmaatụ gas nitrocarburizing). Isi ihe mere e ji echekwa carbonitriding gas dị n'etiti okpomọkụ bụ ime ka ike ígwè sie ike, ike iyi na ike ọgwụgwụ dịkwuo mma. Ọkụ gas dị ala na-esi n'okpuru nitriding, isi ihe kpatara ya bụ ime ka ike iyi nke ígwè na ike ịta ahụhụ dịkwuo mma.

10, Ọgwụgwọ Mgbaze (nkwụsị na ịgbaze): a ga-eme ka ihe a na-eme n'ozuzu ya dị jụụ ma mee ka ọ dị jụụ n'oge okpomọkụ dị elu yana ọgwụgwọ okpomọkụ a maara dị ka ọgwụgwọ mgbaze. A na-ejikarị ọgwụgwọ mgbaze eme ihe n'ọtụtụ akụkụ dị mkpa, karịsịa ndị na-arụ ọrụ n'okpuru ibu ígwè njikọ, bolts, gia na shafts. Site na ọgwụgwọ mgbaze eme ihe iji mee ka sohnite dị nro, ihe ndị dị na ya dị mma karịa otu ike nke nhazi sohnite nkịtị. Ike ya dabere na okpomọkụ dị elu na nkwụsi ike nke ígwè na nha akụkụ ọrụ, n'ozuzu ya n'etiti HB200-350.

11, Brazing: na ihe brazing ga-abụ ụdị ọrụ abụọ nke ikpo ọkụ agbaze agbaze jikọtara ọnụ usoro ọgwụgwọ okpomọkụ.

II.Tnjirimara nke usoro ahụ

Ọgwụgwọ okpomọkụ ígwè bụ otu n'ime usoro dị mkpa n'ịmepụta igwe, ma e jiri ya tụnyere usoro igwe ndị ọzọ, ọgwụgwọ okpomọkụ anaghị agbanwe ọdịdị nke ọrụ ahụ na ihe mejupụtara kemịkalụ dum, kama site n'ịgbanwe obere nhazi dị n'ime nke ọrụ ahụ, ma ọ bụ gbanwee ihe mejupụtara kemịkalụ nke elu nke ọrụ ahụ, iji nye ma ọ bụ melite ojiji nke ihe owuwu ahụ. A na-amata ya site na mmụba na ịdị mma dị n'ime nke ọrụ ahụ, nke anya na-anaghị ahụ anya. Iji mee ọrụ ígwè ahụ nwere ihe owuwu ígwè achọrọ, ihe onwunwe anụ ahụ na ihe onwunwe kemịkalụ, na mgbakwunye na nhọrọ ezi uche dị na ya nke ihe na usoro ịkpụzi dị iche iche, usoro ọgwụgwọ okpomọkụ na-adịkarị mkpa. Ígwè bụ ihe eji eme ihe n'ọtụtụ ebe na ụlọ ọrụ igwe, enwere ike ijikwa mgbagwoju anya ígwè microstructure, site na ọgwụgwọ okpomọkụ, yabụ ọgwụgwọ okpomọkụ nke ígwè bụ isi ihe dị na ọgwụgwọ okpomọkụ ígwè. Na mgbakwunye, aluminom, ọla kọpa, magnesium, titanium na alloys ndị ọzọ nwekwara ike ịbụ ọgwụgwọ okpomọkụ iji gbanwee ihe onwunwe igwe, anụ ahụ na kemịkalụ ya, iji nweta arụmọrụ dị iche iche.

nke atọ.Tọ na-ahazi

Usoro ọgwụgwọ okpomọkụ na-agụnyekarị ikpo ọkụ, ijide, ime ka ọ dị jụụ usoro atọ, mgbe ụfọdụ naanị ikpo ọkụ na ime ka ọ dị jụụ usoro abụọ. Usoro ndị a jikọtara onwe ha, enweghị ike ịkwụsị.

Ịkpọ ọkụ bụ otu n'ime usoro dị mkpa nke ọgwụgwọ okpomọkụ. Ọgwụgwọ okpomọkụ ígwè nke ọtụtụ ụzọ ikpo ọkụ, nke mbụ bụ iji kọl na kol dị ka isi iyi okpomọkụ, itinye mmanụ mmiri na gas n'oge na-adịbeghị anya. Ntinye ọkụ eletrik na-eme ka ikpo ọkụ dị mfe ijikwa, ọ dịghịkwa mmetọ gburugburu ebe obibi. Enwere ike ikpo ọkụ nke isi iyi okpomọkụ ndị a ozugbo, kamakwa site na nnu ma ọ bụ ígwè gbazere agbaze, gaa na ihe ndị na-ese n'elu mmiri maka ikpo ọkụ na-apụtaghị ìhè.

Okpomọkụ ígwè, a na-ekpughere workpiece na ikuku, oxidation, decarburization na-emekarị (ya bụ, ọdịnaya carbon dị n'elu akụkụ ígwè iji belata), nke nwere mmetụta dị njọ na ihe ndị dị n'elu nke akụkụ ndị a na-agwọ okpomọkụ. Ya mere, ígwè ahụ kwesịrị ịdị na ikuku a na-achịkwa ma ọ bụ ikuku nchebe, nnu gbazere agbaze na ikpo ọkụ ikuku, mana mkpuchi ma ọ bụ ụzọ nkwakọ ngwaahịa dị maka ikpo ọkụ nchebe.

Okpomọkụ ọkụ bụ otu n'ime ihe dị mkpa nke usoro ọgwụgwọ okpomọkụ, nhọrọ na njikwa nke okpomọkụ ọkụ, bụ iji hụ na ọgwụgwọ okpomọkụ dị mma nke isi ihe ndị a. Okpomọkụ ọkụ na-agbanwe dabere na ihe e ji ígwè agwọ ọrịa na ebumnuche nke ọgwụgwọ okpomọkụ, mana a na-ekpo ọkụ n'ozuzu ya karịa okpomọkụ mgbanwe nke usoro iji nweta nhazi okpomọkụ dị elu. Na mgbakwunye, mgbanwe ahụ chọrọ oge ụfọdụ, yabụ mgbe elu nke ihe eji arụ ọrụ ígwè ahụ iji nweta okpomọkụ okpomọkụ achọrọ, mana a ga-echekwa ya na okpomọkụ a maka oge ụfọdụ, ka okpomọkụ dị n'ime na nke mpụga wee dịrị otu, ka mgbanwe microstructure wee zuru oke, nke a maara dị ka oge njide. Ojiji nke ikpo ọkụ dị elu na ọgwụgwọ okpomọkụ elu, ọnụego okpomọkụ dị oke ngwa ngwa, enweghị oge njide n'ozuzu, ebe ọgwụgwọ okpomọkụ kemịkalụ nke oge njide na-adịkarị ogologo.

Ịjụ oyi bụkwa nzọụkwụ dị oke mkpa n'usoro ọgwụgwọ okpomọkụ, ụzọ oyi si eme n'ihi usoro dị iche iche, ọkachasị iji chịkwaa ọnụego oyi. Ọkwa oyi n'ozuzu bụ nke kacha nwayọ, ime ka ọnụego oyi dị ngwa ngwa, ime ka ọnụego oyi dị ngwa ngwa. Mana n'ihi ụdị ígwè dị iche iche ma nwee ihe dị iche iche achọrọ, dịka ígwè siri ike nke nwere ikuku, enwere ike imenyụ ya na otu ọnụego oyi si eme ka ọ dị mma.

IV.Pnhazi usoro

Enwere ike kewaa usoro ọgwụgwọ okpomọkụ ígwè n'ime usoro ọgwụgwọ okpomọkụ dum, usoro ọgwụgwọ okpomọkụ elu na usoro ọgwụgwọ okpomọkụ kemịkalụ nke ụdị atọ. Dịka usoro ọgwụgwọ okpomọkụ, usoro okpomọkụ na oyi si dị, enwere ike ịmata ọdịiche dị n'etiti ụdị ọ bụla n'ọtụtụ usoro ọgwụgwọ okpomọkụ dị iche iche. Otu ígwè ahụ na-eji usoro ọgwụgwọ okpomọkụ dị iche iche, nwere ike inweta òtù dị iche iche, si otú a nwee ihe onwunwe dị iche iche. Ígwè na ígwè bụ ígwè a na-ejikarị eme ihe n'ụlọ ọrụ, usoro nhazi ígwè bụkwa nke kachasị mgbagwoju anya, yabụ enwere ọtụtụ usoro ọgwụgwọ okpomọkụ ígwè.

Ọgwụgwọ okpomọkụ n'ozuzu bụ ikpo ọkụ zuru oke nke ihe eji arụ ọrụ ahụ, wee jụọ oyi n'ọkwa kwesịrị ekwesị, iji nweta nhazi ígwè achọrọ, iji gbanwee njirimara igwe ya niile nke usoro ọgwụgwọ okpomọkụ ígwè. Ọgwụgwọ okpomọkụ zuru oke nke ígwè dịka ime ka ọ dị ọcha, ime ka ọ dị mma, ime ka ọ dị ọkụ ma mee ka ọ dị jụụ usoro anọ bụ isi.

Usoro pụtara:

Ịkwanye ihe bụ ikpo ọkụ nke ihe eji arụ ọrụ ahụ ruo okpomọkụ kwesịrị ekwesị, dịka ihe e ji arụ ọrụ ahụ si dị na nha ya site na iji oge njide dị iche iche, wee jiri nwayọọ nwayọọ jụọ oyi, ebumnuche ya bụ ime ka nhazi dị n'ime nke ígwè ahụ ruo ma ọ bụ nso ọnọdụ nguzozi, iji nweta arụmọrụ na arụmọrụ dị mma, ma ọ bụ maka ime ka ọ dị ọkụ ọzọ maka nhazi nkwadebe ahụ.

Nhazi bụ na a na-ekpo ọkụ workpiece ruo okpomọkụ kwesịrị ekwesị mgbe ọ jụrụ oyi n'ikuku, mmetụta nke nhazi yiri annealing, naanị iji nweta nhazi ka mma, nke a na-ejikarị eme ihe iji melite arụmọrụ ịkpụ ihe nke ihe ahụ, mana a na-ejikwa ya mgbe ụfọdụ maka akụkụ ndị na-adịghị achọ ihe dị ka ọgwụgwọ okpomọkụ ikpeazụ.

A na-eji mmiri, mmanụ ma ọ bụ nnu ndị ọzọ na-adịghị n'ime ihe, ihe ndị na-eme ka ihe dị n'ime ihe na-eme ka ihe dị n'ime ihe na-eme ka ihe dị n'ime ihe na-eme ka ọ dị ọkụ ma kpuchie ya, n'ime mmiri, mmanụ ma ọ bụ nnu ndị ọzọ na-adịghị n'ime ihe, ihe ndị na-eme ka ihe dị n'ime ihe na-eme ka ihe dị n'ime ihe na-eme ka ọ dị jụụ ngwa ngwa. Mgbe emechara ya, akụkụ ígwè ahụ na-esi ike, mana n'otu oge ahụ na-aghọ ihe na-emebi emebi, iji wepụ ihe na-emebi emebi n'oge, ọ dị mkpa ka a na-ebelata ya n'oge.

Iji belata ike nke akụkụ ígwè, akụkụ ígwè a gbanyụrụ agbanyụ na okpomọkụ kwesịrị ekwesị karịa okpomọkụ ụlọ ma dị ala karịa 650 ℃ maka ogologo oge mkpuchi, wee jụọ oyi, a na-akpọ usoro a tempering. Ịkpọchi, ịhazi, ime ka okpomọkụ dị jụụ bụ ọgwụgwọ okpomọkụ zuru oke na "ọkụ anọ", nke a na-ejikarị quenching na tempering eme ihe, nke a na-ejikarị eme ihe na njikọta, otu dị mkpa. "Ọkụ anọ" nwere okpomọkụ na ọnọdụ oyi dị iche iche, ma mepụta usoro ọgwụgwọ okpomọkụ dị iche. Iji nweta ọkwa ike na ike ụfọdụ, ime ka ọkụ na ime ka okpomọkụ dị elu jikọtara ya na usoro a, nke a maara dị ka tempering. Mgbe emechara ụfọdụ alloys iji mepụta ngwọta siri ike zuru oke, a na-ejide ha na okpomọkụ ụlọ ma ọ bụ na okpomọkụ kwesịrị ekwesị dị ntakịrị elu maka oge dị ogologo iji melite ike, ike, ma ọ bụ magnetism eletriki nke alloy ahụ. A na-akpọ usoro ọgwụgwọ okpomọkụ dị otú ahụ ọgwụgwọ ịka nká.

Nhazi nrụgide na ọgwụgwọ okpomọkụ jikọtara nke ọma ma jupụta ọnụ iji mezuo ya, ka ọrụ ahụ wee nweta ike dị mma, ike site na usoro a maara dị ka ọgwụgwọ okpomọkụ mmebi; na ikuku nrụgide na-adịghị mma ma ọ bụ oghere na ọgwụgwọ okpomọkụ a maara dị ka ọgwụgwọ okpomọkụ ikuku, nke ọ bụghị naanị nwere ike ime ka ọrụ ahụ ghara ịdị ọcha, anaghị emebi emebi, na-edebe elu nke ọrụ ahụ mgbe ọgwụgwọ gasịrị, na-eme ka arụmọrụ nke ọrụ ahụ ka mma, kamakwa site na ihe nnọchi anya osmotic maka ọgwụgwọ okpomọkụ kemịkalụ.

Ọgwụgwọ okpomọkụ n'elu bụ naanị ikpo ọkụ n'elu akwa ọrụ iji gbanwee ihe ndị dị na akwa elu nke usoro ọgwụgwọ okpomọkụ ígwè. Iji kpoo naanị akwa elu nke akwa ọrụ ahụ na-enweghị mbufe okpomọkụ gabigara ókè n'ime akwa ọrụ ahụ, ojiji nke isi iyi okpomọkụ ga-enwerịrị njupụta ike dị elu, ya bụ, na mpaghara nkeji nke ihe ọrụ ahụ iji nye ike okpomọkụ ka ukwuu, ka akwa elu nke ihe ọrụ ahụ ma ọ bụ nke dị n'ebe ahụ wee nwee ike ịdị obere oge ma ọ bụ ozugbo iru okpomọkụ dị elu. Ọgwụgwọ okpomọkụ n'elu nke ụzọ ndị bụ isi nke ịgbanyụ ọkụ na ọgwụgwọ okpomọkụ induction, isi iyi okpomọkụ a na-ejikarị eme ihe dị ka ọkụ oxacetylene ma ọ bụ oxypropane, ọkụ induction, laser na electron beam.

Ọgwụgwọ okpomọkụ kemịkalụ bụ usoro ọgwụgwọ okpomọkụ ígwè site na ịgbanwe nhazi kemịkalụ, nhazi na ihe onwunwe nke oyi akwa elu nke ihe eji arụ ọrụ ahụ. Ọgwụgwọ okpomọkụ kemịkalụ dị iche na ọgwụgwọ okpomọkụ elu n'ihi na nke mbụ na-agbanwe nhazi kemịkalụ nke oyi akwa elu nke ihe eji arụ ọrụ ahụ. A na-etinye ọgwụgwọ okpomọkụ kemịkalụ na ihe eji arụ ọrụ nke nwere carbon, nnu media ma ọ bụ ihe ndị ọzọ na-agwakọta nke ihe na-eme ka ọ dị n'ime ọkụ, mkpuchi maka oge dị ogologo, nke mere na oyi akwa elu nke ihe eji arụ ọrụ ahụ na-abanye na carbon, nitrogen, boron na chromium na ihe ndị ọzọ. Mgbe etinyere ihe ndị dị n'ime ya, na mgbe ụfọdụ usoro ọgwụgwọ okpomọkụ ndị ọzọ dị ka quenching na tempering. Ụzọ ndị bụ isi nke ọgwụgwọ okpomọkụ kemịkalụ bụ kaburizing, nitriding, ntinye ígwè.

Ọgwụgwọ okpomọkụ bụ otu n'ime usoro dị mkpa n'ime usoro mmepụta nke akụkụ igwe na ebu. N'ozuzu, ọ nwere ike hụ ma melite ihe dị iche iche nke ihe eji arụ ọrụ ahụ, dịka iguzogide iyi, iguzogide nchara. Ọ nwekwara ike imeziwanye nhazi nke ọnọdụ oghere na nrụgide, iji mee ka nhazi dị iche iche nke oyi na ọkụ dị mfe.

Dịka ọmụmaatụ: ígwè a kpụrụ akpụ ọcha mgbe ogologo oge gasịrị, enwere ike nweta ígwè a kpụrụ akpụ a na-agbanwe agbanwe, melite ike; gia nwere usoro ọgwụgwọ okpomọkụ kwesịrị ekwesị, ndụ ọrụ nwere ike ịdị karịa gia a kpụrụ akpụ a na-ekpo ọkụ ugboro ugboro ma ọ bụ ọtụtụ ugboro; na mgbakwunye, ígwè carbon dị ọnụ ala site na ntinye nke ụfọdụ ihe alloying nwere arụmọrụ ígwè alloy dị oke ọnụ, nwere ike dochie ụfọdụ ígwè na-eguzogide okpomọkụ, ígwè anaghị agba nchara; ebu na ihe ndị ọzọ fọrọ nke nta ka ọ bụrụ ihe niile dị mkpa ka a na-eme ọgwụgwọ okpomọkụ. Enwere ike iji ya naanị mgbe ọgwụgwọ okpomọkụ gasịrị.

Ihe mgbakwunye

I. Ụdị nke ịchacha ihe

Ịkpọchi ihe bụ usoro ọgwụgwọ okpomọkụ nke a na-eji ekpo ọkụ ihe e ji arụ ọrụ ruo okpomọkụ kwesịrị ekwesị, jide ya ruo oge ụfọdụ, wee jiri nwayọọ nwayọọ jụọ oyi.

E nwere ọtụtụ ụdị usoro annealing ígwè, dịka usoro annealing si dị, enwere ike kewaa okpomọkụ ọkụ ụzọ abụọ: otu dị na okpomọkụ dị mkpa (Ac1 ma ọ bụ Ac3) n'elu annealing, nke a makwaara dị ka annealing mgbanwe nkebi, gụnyere annealing zuru oke, annealing na-ezughị ezu, annealing spheroidal na diffusion annealing (homogenization annealing), wdg.; nke ọzọ dị n'okpuru okpomọkụ dị mkpa nke annealing, gụnyere recrystallization annealing na de-stressing annealing, wdg. Dịka usoro oyi si dị, anealing nwere ike kewaa n'ime isothermal annealing na continuous cooling annealing.

1, annealing zuru oke na isothermal annealing

A na-akpọkwa annealing zuru oke, nke a makwaara dị ka recrystallization annealing, nke a na-akpọkarị annealing, ọ bụ ígwè ma ọ bụ ígwè a na-ekpo ọkụ ruo Ac3 n'elu 20 ~ 30 ℃, mkpuchi ogologo oge iji mee ka nzukọ ahụ dị ike kpamkpam mgbe ọ jụrụ oyi nwayọ, iji nweta nhazi nhazi nke usoro ọgwụgwọ okpomọkụ. A na-ejikarị annealing a eme ihe maka ihe mejupụtara sub-eutectic nke ọtụtụ ihe nkedo ígwè carbon na alloy, forgings na profaịlụ ọkụ-rolled, a na-ejikwa ya mgbe ụfọdụ maka ihe owuwu welded. Ọtụtụ mgbe, ọ bụ ọtụtụ ihe eji arụ ọrụ na-adịghị arọ, ma ọ bụ dị ka ọgwụgwọ okpomọkụ tupu oge eruo nke ụfọdụ ihe eji arụ ọrụ.

2, ịkụ bọọlụ

A na-ejikarị Spheroidal annealing eme ihe maka ígwè carbon na-anaghị arụ ọrụ nke ọma (dịka imepụta ngwaọrụ dị nkọ, ihe nha, ebu na ihe ndị e ji arụ ọrụ n'ime ígwè ahụ). Isi ihe kpatara ya bụ ibelata ike ya, ime ka igwe ya dịkwuo mma, na ịkwadebe maka imenyụ ya n'ọdịnihu.

3, iwepụ nrụgide

A na-ejikarị annealing a eme ihe iji wepụ ihe e ji kpụọ ihe, ihe e ji kpụọ ihe, ihe e ji agwakọta ihe, ihe e ji kpụọ ihe, ihe ndị a na-akpọ ekpo ọkụ, ihe ndị a na-adọkpụ oyi na ihe ndị ọzọ na-eme ka ha ghara ịdị mma. Ọ bụrụ na e wepụghị nrụgide ndị a, ọ ga-eme ka ígwè dị n'ime ya mgbe oge ụfọdụ gasịrị, ma ọ bụ n'oge ịkpụ ihe na-esote, mee ka ọ ghara ịdị mma ma ọ bụ gbawaa agbawa.

4. Ịkpọcha ihe na-ezughị ezu bụ ikpo ọkụ ígwè ahụ ruo Ac1 ~ Ac3 (ígwè dị n'okpuru eutectic) ma ọ bụ Ac1 ~ ACcm (ígwè karịrị akarị) n'etiti nchekwa okpomọkụ na ịjụ oyi nwayọ iji nweta nhazi zuru oke nke usoro ọgwụgwọ okpomọkụ.

II.Iji mee ka ihe dị jụụ, ihe a na-ejikarị eme ihe bụ brine, mmiri na mmanụ.

Mmiri nnu nke workpiece, ọ dị mfe inweta ike dị elu na elu dị larịị, ọ dịghị mfe imepụta quench, ọ bụghị ntụpọ siri ike, mana ọ dị mfe ime ka workpiece deformation dị njọ, ọbụnakwa gbawaa. Ojiji mmanụ dị ka ihe na-eme ka ihe na-eme ka ihe na-eme ka ihe na-eme ka ihe na-eme ka ihe dị oke mma dabara adaba maka nkwụsi ike nke austenite dị oke ukwuu na ụfọdụ ígwè alloy ma ọ bụ obere nha nke workpiece carbon steel quenching.

nke atọ.ebumnuche nke ime ka ígwè dị nro

1, belata mgbawa, wepụ ma ọ bụ belata nrụgide dị n'ime, imenyụ ígwè emenyụ nwere nnukwu nrụgide dị n'ime na mgbawa dị iche iche, dịka enweghị nhazi oge ga-emekarị ka ígwè ahụ gbanwee ma ọ bụ ọbụna gbawaa.

2, iji nweta ihe eji arụ ọrụ dị mkpa nke ihe eji arụ ọrụ ahụ, mgbe emechara ka ike na mgbawa dị elu kwụsị, iji mezuo ihe achọrọ maka ihe dị iche iche nke ihe eji arụ ọrụ dị iche iche, ị nwere ike ịgbanwe ike ahụ site na iji tempering kwesịrị ekwesị iji belata mgbawa nke ike achọrọ, plastik.

3, Mee ka nha nke workpiece guzosie ike

4, maka annealing siri ike ime ka ụfọdụ ígwè alloy dị nro, na quenching (ma ọ bụ normalize) a na-ejikarị eme ihe mgbe okpomọkụ dị elu gasịrị, ka ígwè carbide kwesịrị ekwesị jikọta ya, ike ga-ebelata, iji mee ka ịkpụ na nhazi dị mfe.

Echiche ndị ọzọ

1, ime ka ihe dị ọcha ghara ịdị ọcha: na-ezo aka na ihe ndị e ji ígwè mee ka ha dị ọkụ ruo okpomọkụ kwesịrị ekwesị, nke a na-echekwa ruo oge ụfọdụ, wee jiri nwayọọ nwayọọ mee ka ha dị jụụ. Usoro ime ka ihe dị ọcha ghara ịdị nkọ bụ: ime ka ihe dị ọcha ghara ịdị nkọ, ime ka ihe dị nro ghara ịdị nkọ, ime ka ihe dị ọcha ghara ịdị nkọ, ime ka ihe dị ọcha ghara ịdị nkọ, wdg. Ebumnuche nke ime ka ihe dị ọcha ghara ịdị nkọ: iji belata ike nke ihe ndị e ji ígwè mee, ime ka ihe dị nro ma ọ bụ nke nrụgide dị mfe, iji mee ka ihe dị nro ma ọ bụ nke nrụgide dị mfe, belata nrụgide fọdụrụ, melite nhazi na nhazi nke njikọta ahụ, ma ọ bụ maka ọgwụgwọ okpomọkụ nke ikpeazụ iji mee ka nzukọ ahụ dị njikere.

2, nhazi: na-ezo aka na ígwè ma ọ bụ ígwè a na-ekpo ọkụ na ma ọ bụ (ígwè na ebe okpomọkụ dị oke mkpa) dị n'elu, 30 ~ 50 ℃ iji nọgide na-enwe oge kwesịrị ekwesị, na-ajụ oyi na usoro ọgwụgwọ okpomọkụ ikuku dị jụụ. Ebumnuche nke ịhazi: ọkachasị iji melite ihe onwunwe nke ígwè carbon dị ala, melite ịkpụ na igwe, nhazi ọka, iji wepụ ntụpọ nhazi, maka ọgwụgwọ okpomọkụ nke ikpeazụ iji kwadebe nzukọ ahụ.

3, imenyụ ọkụ: na-ezo aka na ígwè a na-ekpo ọkụ na Ac3 ma ọ bụ Ac1 (ígwè n'okpuru ebe okpomọkụ dị oke mkpa) n'elu okpomọkụ ụfọdụ, debe oge ụfọdụ, wee ruo na ọnụego oyi kwesịrị ekwesị, iji nweta nhazi martensite (ma ọ bụ bainite) nke usoro ọgwụgwọ okpomọkụ. Usoro imenyụ ọkụ a na-ahụkarị bụ imenyụ ọkụ otu-etiti, imenyụ ọkụ abụọ-etiti, imenyụ ọkụ martensite, imenyụ ọkụ isothermal bainite, imenyụ ọkụ elu na imenyụ ọkụ mpaghara. Ebumnuche nke imenyụ ọkụ: ka akụkụ ígwè wee nweta nhazi martensitic achọrọ, melite ike nke ọrụ ahụ, ike na iguzogide abrasion, maka ọgwụgwọ okpomọkụ nke ikpeazụ iji mee nkwadebe dị mma maka nzukọ ahụ.

4, tempering: na-ezo aka na ígwè siri ike, wee kpoo ya ọkụ ruo okpomọkụ dị n'okpuru Ac1, na-ejide oge, wee jụọ oyi ruo usoro ọgwụgwọ okpomọkụ ụlọ. Usoro tempering ndị a na-ahụkarị bụ: tempering dị ala, tempering dị n'etiti, tempering dị elu na multiple tempering.

Ebumnuche nke ime ka ihe dị jụụ: karịsịa iji wepụ nrụgide nke ígwè ahụ na-emepụta n'ime ihe na-eme ka ihe dị jụụ, ka ígwè ahụ wee nwee ike siri ike ma na-eyi ya, ma nwee ike na ike dị mkpa.

5, tempering: na-ezo aka na ígwè ma ọ bụ ígwè maka imenyụ na ime ka okpomọkụ dị elu nke usoro ọgwụgwọ okpomọkụ mejupụtara. A na-eji ya eme ihe na ọgwụgwọ tempering nke ígwè a na-akpọ tempered steel. Ọ na-ezo aka na ígwè nhazi carbon dị ọkara na ígwè nhazi carbon dị ọkara.

6, ime ka atom carbon banye n'ime akwa elu ígwè. Ọ bụkwa ime ka ihe eji arụ ọrụ ígwè dị ala nke nwere akwa elu ígwè carbon dị elu, wee mechaa mgbe emechara ya ma mee ka okpomọkụ dị ala dị ala, ka akwa elu nke ihe eji arụ ọrụ ahụ nwee ike siri ike ma na-eguzogide iyi, ebe akụkụ etiti nke ihe eji arụ ọrụ ahụ ka na-ejigide ike na plasticity nke obere ígwè carbon.

Usoro uzuoku

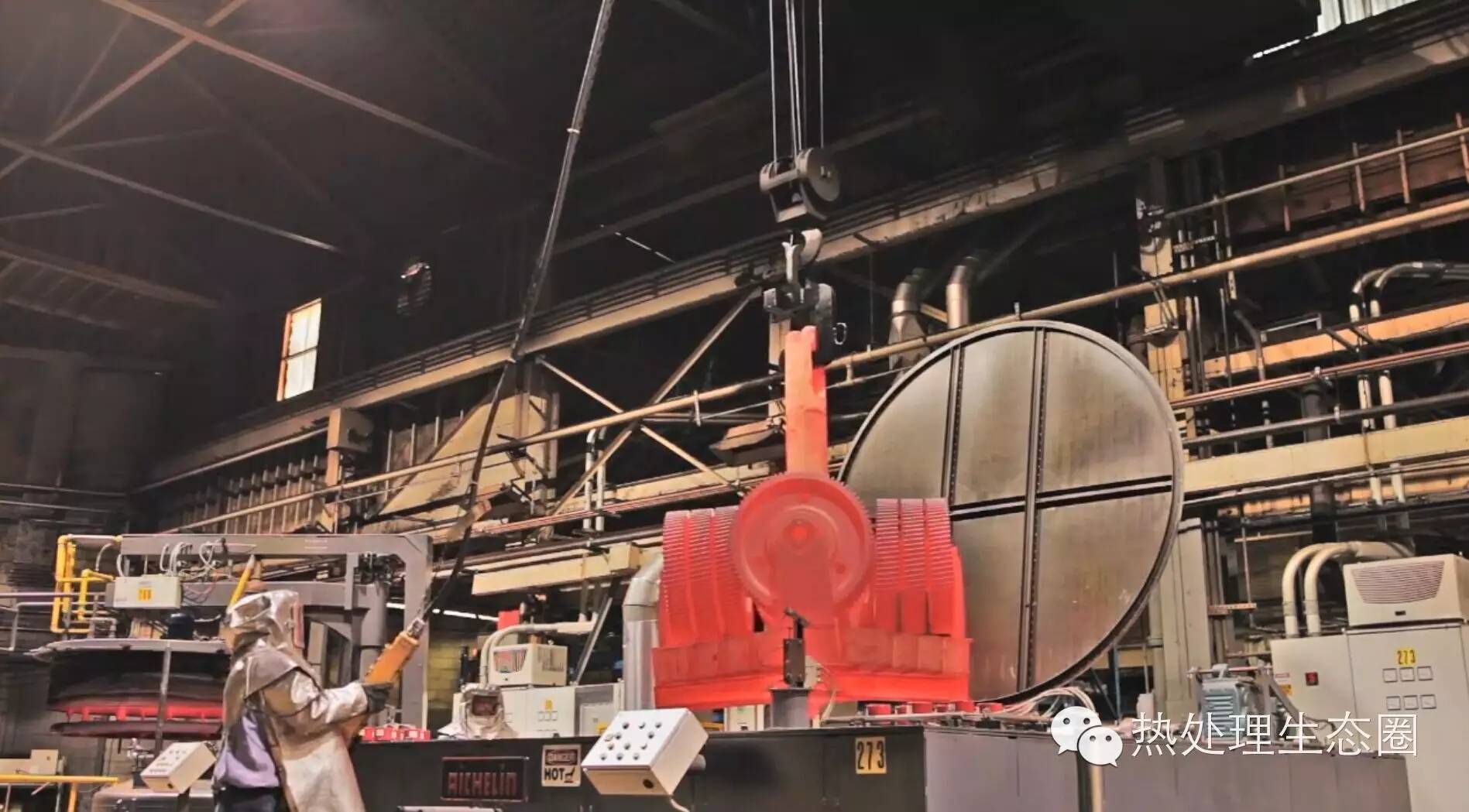

Ebe ọ bụ na ọrụ ikpo ọkụ na oyi nke ihe eji arụ ọrụ ígwè chọrọ ihe dị ka iri na abụọ ma ọ bụ ọtụtụ ihe iji mezue. A na-eme ihe ndị a n'ime ọkụ ọkụ na-arụ ọrụ, onye ọrụ agaghị enwe ike ịbịaru nso, yabụ ọkwa nke akpaaka nke ọkụ ọkụ na-arụ ọrụ okpomọkụ dị elu. N'otu oge ahụ, ụfọdụ ihe omume, dị ka ikpo ọkụ na ijide njedebe nke usoro ikpo ọkụ ígwè ga-abụ ihe omume isii, asaa ma mechaa ya n'ime sekọnd 15. Ọnọdụ ndị dị otú ahụ dị mfe iji mezue ọtụtụ ihe omume, ọ dị mfe ime ka onye ọrụ nwee ụjọ ma bụrụ ọrụ na-ezighi ezi. Ya mere, naanị oke akpaghị aka nwere ike ịbụ nhazi ziri ezi na nke oge dịka mmemme ahụ si dị.

A na-eme ọgwụgwọ okpomọkụ nke akụkụ ígwè n'ime ọkụ ikuku mechiri emechi, a maara nke ọma mkpuchi ikuku siri ike. Ya mere, iji nweta ma rapara na ọnụego ikuku mbụ nke ọkụ ọkụ ahụ, iji hụ na oghere ọrụ nke ọkụ ikuku ahụ, iji hụ na ụdị akụkụ ahụ ọgwụgwọ okpomọkụ ikuku ahụ dị oke mkpa. Ya mere, isi okwu nke ọkụ ọkụ ọgwụgwọ okpomọkụ ikuku bụ inwe usoro mkpuchi ikuku a pụrụ ịdabere na ya. Iji hụ na arụmọrụ oghere nke ọkụ ikuku ahụ, nhazi nhazi ọkụ ọkụ ikuku ga-agbaso ụkpụrụ bụ isi, ya bụ, ahụ ọkụ iji jiri njikọta gas na-anaghị emerụ ahụ, ebe ahụ ọkụ dị ka o kwere mee imepe ma ọ bụ ghara imepe oghere ahụ, obere ma ọ bụ zere iji usoro mkpuchi ike, iji belata ohere maka oghere ikuku. E tinyere na akụkụ ahụ ọkụ ikuku ahụ, ngwa, dị ka elektrọd mmiri oyi, ngwaọrụ mbupụ thermocouple ga-emekwa ka ọ mechie usoro ahụ.

Enwere ike iji ọtụtụ ihe ndị e ji ekpo ọkụ na ihe mkpuchi naanị n'okpuru oghere ikuku. Ọkụ ọkụ na ihe mkpuchi mkpuchi okpomọkụ dị n'ime oghere ikuku ikuku na okpomọkụ dị elu, yabụ ihe ndị a na-ebute oke iguzogide okpomọkụ, nsonaazụ radieshon, ike ikuku ikuku na ihe ndị ọzọ achọrọ. Ihe achọrọ maka iguzogide oxidation adịghị elu. Ya mere, tantalum, tungsten, molybdenum na graphite nke a na-ejikarị eme ihe maka ihe mkpuchi okpomọkụ na ihe mkpuchi okpomọkụ. Ihe ndị a dị mfe ịgbaze n'ọnọdụ ikuku, ya mere, ọkụ ọkụ nkịtị enweghị ike iji ihe ndị a na-ekpo ọkụ na ihe mkpuchi.

Ngwaọrụ eji eme ka mmiri jụọ oyi: shei ọkụ ọkụ, mkpuchi ọkụ, ihe ndị na-ekpo ọkụ eletrik, elektrọd mmiri oyi, ọnụ ụzọ mkpuchi okpomọkụ dị n'etiti na ihe ndị ọzọ, dị n'ime oghere, n'okpuru ọnọdụ okpomọkụ. Mgbe ọ na-arụ ọrụ n'ọnọdụ dị oke njọ, a ga-ahụ na nhazi nke ihe ọ bụla adịghị mma ma ọ bụ mebie, nakwa na mkpuchi ikuku anaghị ekpo oke ọkụ ma ọ bụ gbaa ọkụ. Ya mere, a ga-edozi akụkụ ọ bụla dịka ọnọdụ dị iche iche si dị, ngwaọrụ mmiri oyi iji hụ na ọkụ ọkụ okpomọkụ ahụ nwere ike ịrụ ọrụ nke ọma ma nwee ndụ zuru oke.

Ojiji nke obere voltaji dị elu: akpa vacuum, mgbe ọkwa vacuum vacuum nke ole na ole lxlo-1 torr, akpa vacuum nke onye na-eduzi ike na voltaji dị elu, ga-emepụta ihe na-enwu enwu. N'ime ọkụ ọkụ vacuum, mwepụ arc dị njọ ga-agba ihe na-ekpo ọkụ eletrik ọkụ, oyi akwa mkpuchi, na-akpata nnukwu ihe mberede na mfu. Ya mere, ọkụ ọkụ ọkụ eletrik na-arụ ọrụ voltaji anaghị agafe 80 a 100 volts. N'otu oge ahụ na nhazi ihe na-ekpo ọkụ eletrik iji mee ihe dị irè, dịka ịnwa izere inwe nsọtụ nke akụkụ, oghere electrode n'etiti elektrọd enweghị ike ịdị obere, iji gbochie mmepụta nke mwepụ glow ma ọ bụ mwepụ arc.

Na-eme ka ahụ dị jụụ

Dịka ihe dị iche iche achọrọ maka arụmọrụ nke workpiece ahụ si dị, dịka okpomọkụ dị iche iche ya si dị, enwere ike kewaa ya n'ime ụdị tempering ndị a:

(a) ime ka okpomọkụ dị ala (ogo 150-250)

Ndozi okpomọkụ dị ala nke nhazi nke a na-emepụta maka martensite dị ọkụ. Ebumnuche ya bụ ịnọgide na-enwe ike siri ike na ike dị elu nke ígwè a gbanyụrụ agbanyụ n'okpuru echiche nke ibelata nrụgide dị n'ime ya na ike ya, iji zere mmebi ma ọ bụ mmebi tupu oge eruo n'oge ojiji. A na-ejikarị ya eme ihe maka ọtụtụ ngwaọrụ ịkpụ carbon dị elu, ihe nha, ihe ndị na-adọkpụ oyi, ihe ndị na-agbagharị agbagharị na akụkụ ndị a na-akpọ carburized, wdg., mgbe ike tempering na-abụkarị HRC58-64.

(ii) ime ka okpomọkụ dị n'etiti (ogo 250-500)

Nhazi okpomọkụ dị n'etiti maka ahụ quartz dị nro. Ebumnuche ya bụ inweta ike mmepụta dị elu, oke mgbanwe na ike dị elu. Ya mere, a na-ejikarị ya eme ihe maka ọtụtụ isi iyi na nhazi ebu ọkụ, ike nrụpụta na-abụkarị HRC35-50.

(C) okpomọkụ dị elu (ogo 500-650)

Nhazi okpomọkụ dị elu nke nzukọ maka Sohnite dị ọkụ. Nhazi okpomọkụ a na-ejikarị eme ihe na nhazi okpomọkụ dị elu nke a maara dị ka ọgwụgwọ okpomọkụ, ebumnuche ya bụ inweta ike, ike na plasticity, ike bụ ihe onwunwe igwe ka mma n'ozuzu ya. Ya mere, a na-ejikarị ya eme ihe n'ụgbọala, traktọ, ngwaọrụ igwe na akụkụ nhazi ndị ọzọ dị mkpa, dị ka mkpanaka njikọ, bolts, gia na shafts. Ike mgbe a gbasịrị okpomọkụ na-abụkarị HB200-330.

Mgbochi mgbanwe

Ihe ndị na-akpata mgbanwe ebu dị mgbagwoju anya na-abụkarị ihe mgbagwoju anya, mana anyị na-amụta naanị iwu mgbanwe ya, na-enyocha ihe kpatara ya, na-eji ụzọ dị iche iche egbochi mgbanwe ebu nwere ike ibelata, mana nweekwa ike ijikwa ya. N'ozuzu, ọgwụgwọ okpomọkụ nke mgbanwe ebu dị mgbagwoju anya nwere ike iji ụzọ ndị a nke mgbochi.

(1) Nhọrọ ihe ezi uche dị na ya. E kwesịrị ịhọrọ ihe e ji ebu dị mgbagwoju anya nke ọma, ígwè e ji ebu dị nro (dịka ígwè e ji eme ka ikuku ghara ịpụ), nkewa carbide nke ígwè e ji ebu dị oké njọ kwesịrị ịbụ ihe ezi uche dị na ya maka ịkpụ na ime ka okpomọkụ dị jụụ, ígwè e ji ebu buru ibu ma bụrụ nke a na-apụghị ịgbagha agbagha nwere ike ịbụ ngwọta siri ike maka nhazi okpomọkụ okpukpu abụọ.

(2) Nhazi nhazi ebu kwesịrị ịbụ ihe ezi uche dị na ya, ọkpụrụkpụ ekwesịghị ịdị oke iche, ọdịdị ahụ kwesịrị ịdị ka ihe nhata, maka mgbanwe nke ebu buru ibu iji mara iwu mgbanwe, enwere ike iji ikike nhazi echekwara, maka ebu buru ibu, nke ziri ezi na nke dị mgbagwoju anya na njikọta nke ihe owuwu.

(3) E kwesịrị iji usoro nhazi na ihe ndị dị mgbagwoju anya mee ihe tupu e kpoo ọkụ iji wepụ nrụgide fọdụrụnụ nke e mepụtara n'ime usoro nhazi.

(4) Nhọrọ ezi uche dị na ya nke okpomọkụ ikpo ọkụ, ijikwa ọsọ ikpo ọkụ, maka ebu ndị dị mgbagwoju anya nke ziri ezi nwere ike iji obere oge kpo oku, kpo oku tupu oge eruo na ụzọ ndị ọzọ e si ekpo ọkụ iji belata mgbanwe ọgwụgwọ okpomọkụ ebu.

(5) N'okpuru echiche nke ijide n'aka na ebu ahụ siri ike, gbalịa iji usoro tupu oyi, usoro oyi ma ọ bụ usoro ikpo ọkụ.

(6) Maka nkenke na ihe ndị dị mgbagwoju anya, dịka ọnọdụ si dị, gbalịa iji ihe na-ekpo ọkụ na ihe na-eme ka ọ dị jụụ mgbe emechara ya.

(7) Maka ụfọdụ nkenke na ihe mgbagwoju anya, enwere ike iji ọgwụgwọ okpomọkụ tupu oge eruo, ọgwụgwọ okpomọkụ ịka nká, ọgwụgwọ okpomọkụ nitriding iji chịkwaa izi ezi nke ebu ahụ.

(8) N'ịrụzi oghere ájá ebu, oghere, iyi na ntụpọ ndị ọzọ, iji igwe ịgbado ọkụ oyi na mmetụta okpomọkụ ndị ọzọ nke ngwaọrụ ndozi iji zere usoro nrụzi nke mgbanwe.

Tinyere nke ahụ, ọrụ usoro ọgwụgwọ okpomọkụ ziri ezi (dịka nkwụnye oghere, oghere e kegidere, nhazi igwe, ụzọ kpo oku kwesịrị ekwesị, nhọrọ ziri ezi nke ntụziaka oyi nke ebu na ntụziaka mmegharị na usoro oyi, wdg) na usoro ọgwụgwọ okpomọkụ dị mma bụ ibelata mgbanwe nke nkenke na ebu dị mgbagwoju anya bụkwa ihe ndị dị irè.

A na-ejikarị ọkụ induction ma ọ bụ ọkụ ọkụ eme ọgwụgwọ okpomọkụ iji mechie elu na ime ka ọ dị jụụ. Isi ihe ndị dị mkpa bụ ike elu, ike mpaghara na omimi nke oyi akwa siri ike. Enwere ike iji nnwale ike Vickers, enwere ike iji Rockwell ma ọ bụ igwe nnwale ike Rockwell dị n'elu. Nhọrọ nke ike ule (nha) metụtara omimi nke oyi akwa siri ike dị irè na ike elu nke ọrụ ahụ. Ụdị igwe nnwale ike atọ dị ebe a.

Nke mbụ, ihe nnwale ike Vickers bụ ụzọ dị mkpa isi nwalee ike elu nke ihe eji arụ ọrụ a na-agwọ okpomọkụ, enwere ike ịhọrọ ya site na 0.5 ruo 100kg nke ike nnwale, nwalee oyi akwa ike elu dị ka ọkpụrụkpụ dị 0.05mm, izi ezi ya bụkwa nke kachasị elu, ọ nwekwara ike ịmata ọdịiche dị nta na ike elu nke ihe eji arụ ọrụ a na-agwọ okpomọkụ. Na mgbakwunye, ihe nnwale ike Vickers kwesịkwara ịchọpụta omimi nke oyi akwa siri ike dị irè, yabụ maka nhazi ọgwụgwọ okpomọkụ elu ma ọ bụ ọtụtụ nkeji na-eji ihe eji arụ ọrụ a na-agwọ okpomọkụ elu, nke nwere ihe nnwale ike Vickers.

Nke abụọ, ihe nnwale ike Rockwell dị n'elu dịkwa mma maka ịnwale ike nke ihe eji arụ ọrụ siri ike n'elu, ihe nnwale ike Rockwell dị n'elu nwere nha atọ ịhọrọ. Nwere ike ịnwale omimi ike dị irè nke ihe karịrị 0.1mm nke ihe eji arụ ọrụ siri ike dị iche iche. Ọ bụ ezie na nkọwapụta ike Rockwell dị n'elu adịghị elu dị ka ihe nnwale ike Vickers, kama dịka njikwa mma nke ụlọ ọrụ ọgwụgwọ okpomọkụ na ụzọ nyocha ruru eru, enweela ike imezu ihe achọrọ. Ọzọkwa, ọ nwekwara ọrụ dị mfe, dị mfe iji, ọnụ ahịa dị ala, nha ngwa ngwa, nwere ike ịgụ uru ike na njirimara ndị ọzọ ozugbo, ojiji nke ihe nnwale ike Rockwell dị n'elu nwere ike ịbụ otu ọrụ ọgwụgwọ okpomọkụ dị n'elu maka nnwale ngwa ngwa na nke na-anaghị emebi emebi. Nke a dị mkpa maka ụlọ ọrụ nhazi ígwè na nrụpụta igwe.

Nke atọ, mgbe ọgwụgwọ okpomọkụ elu dị arọ karịa, enwere ike iji ihe nnwale ike Rockwell. Mgbe ọgwụgwọ okpomọkụ siri ike nke oyi akwa nke 0.4 ~ 0.8mm, enwere ike iji ihe nha HRA, mgbe enwere ike iji ihe nha HRC siri ike nke karịrị 0.8mm.

Enwere ike ịgbanwe ụdị ụkpụrụ ike atọ dị iche iche na Vickers, Rockwell na Rockwell ngwa ngwa, gbanwee ha ka ha bụrụ ọkọlọtọ, eserese ma ọ bụ onye ọrụ chọrọ uru ike. E nyere tebụl mgbanwe ndị kwekọrọ na ọkọlọtọ mba ụwa ISO, ọkọlọtọ America ASTM na ọkọlọtọ China GB/T.

Ike mpaghara

Akụkụ ndị ahụ, ọ bụrụ na ihe siri ike mpaghara chọrọ maka ikpo ọkụ induction dị elu, dị na ụzọ ndị ọzọ e si agwọ okpomọkụ imechi mpaghara, akụkụ ndị a na-abụkarị akara ebe ọgwụgwọ okpomọkụ imechi mpaghara na uru ike mpaghara dị na eserese ndị ahụ. A ga-eme nnwale ike nke akụkụ ndị ahụ n'ebe a họpụtara. Enwere ike iji ngwa nnwale ike Rockwell, nwalee uru ike HRC, dị ka oyi akwa ike imechi ọgwụgwọ okpomọkụ dị obere, enwere ike iji ihe nnwale ike Rockwell elu, nwalee uru ike HRN.

Ọgwụgwọ okpomọkụ kemịkalụ

Ọgwụgwọ okpomọkụ kemịkalụ bụ ime ka elu nke ihe eji arụ ọrụ ahụ banye n'ime otu ma ọ bụ ọtụtụ ihe kemịkalụ nke atọm, ka o wee gbanwee nhazi kemịkalụ, nhazi na arụmọrụ nke elu ihe eji arụ ọrụ ahụ. Mgbe emechara ma belata okpomọkụ, elu nke ihe eji arụ ọrụ ahụ nwere ike siri ike, ike iyi na ike ọgwụgwụ kọntaktị, ebe isi ihe eji arụ ọrụ ahụ nwere ike siri ike.

Dịka e kwuru n'elu, nchọpụta na ndekọ nke okpomọkụ n'usoro ọgwụgwọ okpomọkụ dị oke mkpa, njikwa okpomọkụ na-adịghị mma na-emetụtakwa ngwaahịa ahụ nke ukwuu. Ya mere, nchọpụta nke okpomọkụ dị oke mkpa, usoro okpomọkụ n'usoro ahụ dum dịkwa oke mkpa, nke na-eme ka usoro ọgwụgwọ okpomọkụ dị na mgbanwe okpomọkụ, nwere ike ime ka nyocha data n'ọdịnihu dị mfe, kamakwa iji hụ oge okpomọkụ anaghị emezu ihe achọrọ. Nke a ga-arụ ọrụ dị ukwuu n'imeziwanye ọgwụgwọ okpomọkụ n'ọdịnihu.

Usoro ọrụ

1, Hichaa ebe ọrụ ahụ, lelee ma ọkụ eletrik, ngwa nha na ihe mgba ọkụ dị iche iche hà bụ ihe nkịtị, nakwa ma mmiri ahụ ọ dị ire ụtọ.

2、Ndị ọrụ kwesịrị iyi ezigbo ngwa nchekwa nchedo ọrụ, ma ọ bụghị ya, ọ ga-adị ize ndụ.

3, mepee ihe mgbanwe nnyefe ike njikwa zuru ụwa ọnụ, dịka ihe teknụzụ chọrọ nke akụkụ akụrụngwa nke mmụba na ọdịda okpomọkụ si dị, iji mee ka akụrụngwa na akụrụngwa dịgide ogologo ndụ.

4, iji lebara anya na nhazi okpomọkụ nke ọkụ ọkụ na ọsọ eriri eriri, nwere ike ịmụta ụkpụrụ okpomọkụ achọrọ maka ihe dị iche iche, iji hụ na ike nke workpiece na elu kwụ ọtọ na oyi akwa oxidation siri ike, ma rụọ ọrụ nchekwa dị mma.

5, Iji lebara okpomọkụ na ọsọ eriri ọkụ tempering anya, mepee ikuku ikpochapu, ka workpiece wee mezuo ihe achọrọ maka àgwà ahụ.

6, n'ọrụ ahụ kwesịrị ịrapara na post ahụ.

7, ịhazi ngwa ọkụ dị mkpa, marakwa ụzọ e si eji ya na ụzọ e si edozi ya.

8、Mgbe anyị na-akwụsị igwe ahụ, anyị kwesịrị ịlele ma ihe niile e ji achịkwa ya dị n'ọnọdụ gbanyụrụ, wee mechie ihe niile e ji enyefe ya.

Ịkpo oke ọkụ

Site n'ọnụ siri ike nke ihe eji emegharị ihe, enwere ike ịhụ akụkụ ndị na-ebu ibu mgbe emechara ikpo oke ọkụ microstructure. Mana iji chọpụta kpọmkwem oke okpomọkụ, a ga-ahụrịrị obere nhazi ahụ. Ọ bụrụ na n'ime nhazi GCr15 ígwè quenching na ọdịdị nke agịga siri ike martensite, ọ bụ imechi nhazi oke okpomọkụ. Ihe kpatara e ji emechi okpomọkụ okpomọkụ nwere ike ịdị oke elu ma ọ bụ kpo oku na oge ijide ogologo oge kpatara oke okpomọkụ zuru oke; nwekwara ike ịbụ n'ihi nhazi mbụ nke band carbide siri ike, na obere mpaghara carbon dị n'etiti eriri abụọ ahụ iji mepụta agịga martensite mpaghara dị oke arọ, nke na-ebute oke okpomọkụ mpaghara. Austenite fọdụrụ na nzukọ ahụ na-ekpo oke ọkụ na-abawanye, nkwụsi ike nha na-ebelatakwa. N'ihi oke okpomọkụ nke nhazi quenching, kristal ígwè ahụ dị nkọ, nke ga-eduga na mbelata na ike nke akụkụ ahụ, a na-ebelata iguzogide mmetụta, a na-ebelatakwa ndụ nke bearing ahụ. Oke oke okpomọkụ nwere ike ibute mgbawa quenching.

Kpo oke ọkụ

Okpomọkụ nkwụsị dị ala ma ọ bụ na oyi adịghị mma ga-emepụta ihe karịrị nhazi Torrhenite ọkọlọtọ na microstructure, nke a maara dị ka nzukọ na-ekpo ọkụ na-adịghị ala ala, nke na-eme ka ike ghara ịla, a na-ebelata ike iyi nke ukwuu, na-emetụta ndụ nke akụkụ roller na-ebu.

Imechi mgbawa

Akụkụ ndị na-ebu ibu nke na-agbagharị agbagharị n'ime usoro ịgbanyụ na oyi n'ihi nrụgide dị n'ime, mgbawa ndị a na-akpọ mgbawa ọkụ. Ihe ndị na-akpata mgbawa ndị a bụ: n'ihi ịgbanyụ ọkụ, okpomọkụ dị oke elu ma ọ bụ oyi dị oke ngwa ngwa, nrụgide okpomọkụ na mgbanwe olu ígwè na nhazi nrụgide karịrị ike mgbawa nke ígwè; elu ọrụ nke ntụpọ mbụ (dị ka mgbawa elu ma ọ bụ ọkọ) ma ọ bụ ntụpọ dị n'ime ígwè (dị ka slag, nnukwu ihe ndị na-abụghị ọla, ntụpọ ọcha, ihe fọdụrụ na-ebelata, wdg) na ịgbanyụ nke nhazi nke nrụgide; nnukwu mwepụ elu na nkewa Carbide; akụkụ ndị a gbanyụrụ mgbe a gbanyụrụ ya nke ọma ma ọ bụ na-adịghị mma; nrụgide oyi nke usoro gara aga kpatara buru ibu, ịkpụgharị mpịachi, ịkpụgharị miri emi, oghere mmanụ dị nkọ na ihe ndị ọzọ. Na nkenke, ihe kpatara ịgbanyụ mgbawa nwere ike ịbụ otu ma ọ bụ karịa n'ime ihe ndị dị n'elu, ọnụnọ nke nrụgide dị n'ime bụ isi ihe kpatara e ji agbanyụ mgbawa. Mgbanyụ ọkụ dị omimi ma dị gịrịgịrị, yana mgbawa kwụ ọtọ na enweghị agba oxidized na elu gbajiri agbaji. Ọ na-abụkarị mgbawa dị larịị ma ọ bụ mgbawa dị ka mgbaaka n'olu olu ibu; ọdịdị dị na bọọlụ ígwè na-ebu ya bụ nke S, nke T ma ọ bụ nke mgbaaka. Njirimara nhazi nke ịgbanyụ mgbawa abụghị ihe na-eme ka a ghara ịgbanwe ya n'akụkụ abụọ nke mgbawa ahụ, nke a pụrụ ịmata nke ọma site na ịgbawa mgbawa na mgbawa ihe.

Mgbanwe ọgwụgwọ okpomọkụ

Akụkụ NACHI na-ebu ibu n'ọgwụgwọ okpomọkụ, enwere nrụgide okpomọkụ na nrụgide nhazi, nrụgide dị n'ime a nwere ike ịdị n'elu ibe ha ma ọ bụ gbanwee akụkụ ya, ọ dị mgbagwoju anya ma na-agbanwe agbanwe, n'ihi na enwere ike ịgbanwe ya site na okpomọkụ okpomọkụ, ọnụego okpomọkụ, ọnọdụ oyi, ọnụego oyi, ọdịdị na nha nke akụkụ ahụ, yabụ mgbanwe ọgwụgwọ okpomọkụ agaghị ekwe omume. Ịmata ma mara iwu iwu nwere ike ime ka mgbanwe nke akụkụ na-ebu ibu (dị ka oval nke olu akwa, nha elu, wdg) dị n'ogo a na-achịkwa, na-enyere aka na mmepụta. N'ezie, na usoro ọgwụgwọ okpomọkụ nke nkpọkọ igwe ga-emekwa ka mgbanwe akụkụ ahụ dị, mana enwere ike iji mgbanwe a melite ọrụ iji belata ma zere.

Ịkpụcha elu

Ngwa Roller ndị nwere akụkụ n'usoro ọgwụgwọ okpomọkụ, ọ bụrụ na e kpoo ya ọkụ na ihe na-eme ka ọ dị ọkụ, a ga-eme ka elu ahụ dị oxidized ka akụkụ ndị ahụ wee belata oke oke carbon, nke na-eme ka a ghara ịkpọpụta ya. Omimi nke oyi akwa decarburization elu karịa nhazi ikpeazụ nke oke njide ga-eme ka akụkụ ndị ahụ ghara ịdị mma. Nchọpụta nke omimi nke oyi akwa decarburization elu na nyocha metallographic nke usoro metallographic dị na usoro microhardness. Usoro nkesa microhardness nke oyi akwa elu dabere na usoro nha, enwere ike iji ya dị ka usoro nhazi.

Ebe dị nro

N'ihi okpomọkụ zuru oke, enweghị ezigbo oyi, na ọrụ imenyụ ọkụ nke sitere na ike na-adịghị mma nke akụkụ ndị na-ebu ibu nke ihe na-agbagharị agbagharị abụghị ihe a maara dị ka imenyụ ntụpọ dị nro. Ọ dị ka ime ka ihe na-adịghị mma nke elu nwere ike ibute nnukwu mbelata na ike ọgwụgwụ.

Oge ozi: Disemba-05-2023