1.Nchịkọta Ngwaahịa

Womic Steel bụ ọkachamara n'ịmepụta ọkpọkọ ọla kọpa dị elu nke dabara na ọkọlọtọ EN 1057. E ji ihe Cu-DHP (CW024A) mee ọkpọkọ ndị a, na-eme ka ọ dị ọcha ma na-arụ ọrụ nke ọma maka ọkpọkọ mmiri, nkesa gas, ikpo ọkụ, na ojiji oyi. Site na obere ọdịnaya ọla kọpa na ọlaọcha nke 99.9% na oke phosphorus a na-achịkwa n'etiti 0.015% na 0.040%, ọkpọkọ ọla kọpa anyị na-egosipụta ezigbo iguzogide nchara, ịdịte aka, na ịdị mfe nke nrụnye.

E mepụtara ọkpọkọ ọla kọpa EN 1057 maka ojiji n'ime ụlọ na n'ụlọ ọrụ mmepụta ihe, na-enye arụmọrụ a pụrụ ịdabere na ya na sistemụ mmiri a na-aṅụ, kpo oku etiti, friji, na ọkpọkọ gas ahụike. Ejiri ụkpụrụ dị elu rụọ ya, ọkpọkọ ndị a na-enye ihe eji arụ ọrụ dị elu na ntụkwasị obi ogologo oge.

2.EN 1057 Ọla kọpa Tubes Production Range

● Dayameta Mpụga (OD):6 mm ruo 267 mm

●Ọkpụrụkpụ Mgbidi (WT):0.3mm ruo20mm

●Ogologo:Ogologo ọkọlọtọ nke 3m, 5m, ma ọ bụ 6m; ogologo omenala dị ma ọ bụrụ na achọrọ ya

●Tubes a gbakọtara agwakọta:Dị na coils 25m ma ọ bụ 50m maka nrụnye na-agbanwe agbanwe

3.EN 1057 Ọla kọpa Tubes ndidi

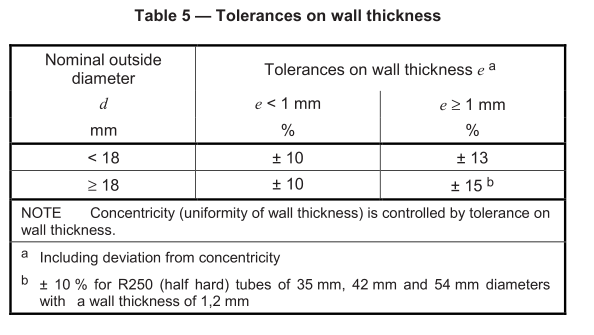

Womic Steel na-eme ka izi ezi nha ziri ezi site na iji ihe ndị a:

4.Ngwakọta kemịkalụ EN 1057 Tubes ọla kọpa

A na-eji ihe Cu-DHP (CW024A) emepụta ọkpọkọ ọla kọpa anyị, ya na ihe ndị a:

Ihe mejupụtara ya ga-agbaso ihe ndị a chọrọ:

Cu + Ag: nkeji. 99,90%;

0,015 %≤P≤0,040 %.

A na-akpọ ọkwa ọla kọpa a Cu-DHP ma ọ bụ CW024A.

Ihe mejupụtara a na-eme ka iguzogide nchara dị mma, ike ọkụ na eletriki dị elu, yana ike ịrụ ọrụ dị elu.

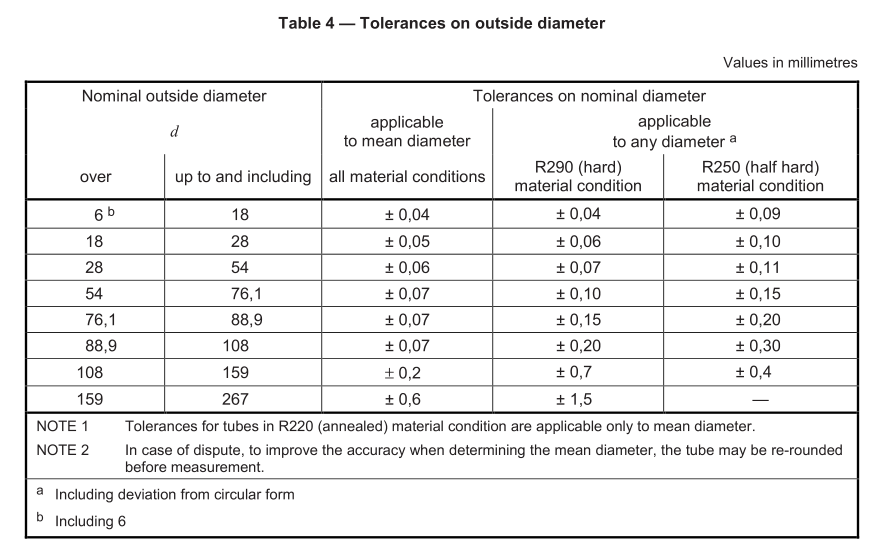

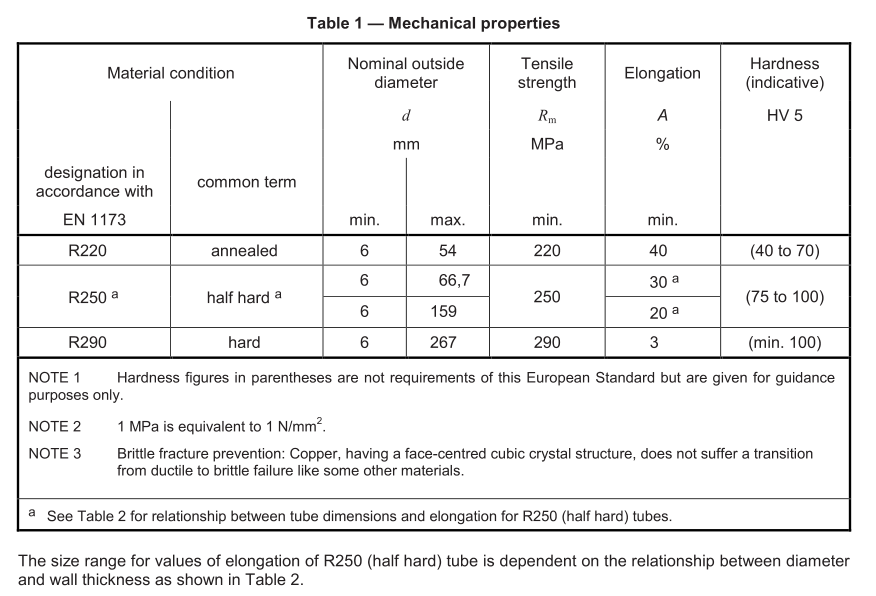

5.Njirimara Mekaniki nke tube ọla kọpa EN 1057

Njirimara igwe nke ọkpọkọ ọla kọpa EN 1057 anyị dabere na ọnọdụ nnyefe:

6.Ọnọdụ nnyefe nke tube ọla kọpa EN 1057

Womic Steel na-enye ọkpọkọ ọla kọpa EN 1057 n'ọnọdụ ndị a:

●R220 (Annealed): Mgbanwe dị ukwuu, dị mma maka ịgbagọ na ịkpụpụta

●R250 (Ọkara-Siri Ike): Ike dị ala, ezigbo nguzozi nke mgbanwe na ịdịte aka

●R290 (Siri Ike): Ike dị elu, dabara adaba maka ngwa kwụ ọtọ na obere mgbagọ

7.Usoro Mmepụta Tubes ọla kọpa EN 1057

Usoro mmepụta anyị dị elu na-eme ka ụkpụrụ kachasị mma dị:

1. Nkwadebe maka Ịkpụ na Ịkpụ: A na-agbaze ọla kọpa dị ọcha ma tụba ya n'ime iberibe.

2. Mbupụ na Ịkpọpu: A na-etinye billets n'ime ụdị tube ma dụpuo ha maka nha achọrọ.

3. Nseta Oyi: A na-adọta tubes site na ihe eji ehicha ihe iji nweta nha ziri ezi.

4. Ịkwanye ọkụ: A na-etinye ọgwụgwọ okpomọkụ iji nweta ihe ndị dị mkpa maka igwe.

5. Ịhazi na Ịcha: A na-agbazi ma bee tubes dịka ogologo ha chọrọ.

6.Nnyocha na Nnwale: Nlele mma siri ike na-eme ka a hụ na e rubere ụkpụrụ EN 1057 isi.

8.Nnwale na Nnyocha

Womic Steel na-ekwe nkwa njikwa mma zuru oke yana nnwale zuru oke, gụnyere:

●Nyocha Kemịkal/Spectrographic: Nyocha nke ihe mejupụtara ihe site na iji usoro kemịkalụ ma ọ bụ spectroscopic.

●Nnwale Mgbatị: Nyocha nke ike mgbatị na njirimara ịgbatị (EN 10002-1).

●Nnwale Ike: Ịtụle ike ihe site na usoro Vickers (EN ISO 6507-1).

●Nnwale Ọdịnaya Kabọn: Nchọpụta ọnụọgụ nke pasentị kabọn site na iji usoro ntụaka EN 723.

●Ule Ihe Nkiri Carbon: Nchọpụta na nyocha nke ọnụnọ ihe nkiri carbon (Mgbakwunye B).

●Ule Ịgbagọ: Nyocha nke ịgbagọ n'okpuru

●Nnwale Mgbasa-Mgbasa: Mgbasawanye nke njedebe tube site na 30% site na45°mandrel conical iji kwado njikwa ductility (EN ISO 8493).

●Nnwale Flanging: Nnwale nke mmepụta flange (opekempe mmụba 30% na dayameta tube) site na iji ngwaọrụ nwere radius nkuku 1 mm (EN ISO 8494).

●Nnwere Onwe Site na Nrụgide:

●Nnwale Eddy Ugbu a (ECT): Nchọpụta nke ntụpọ elu/okpuru ala (EN 1971 & Mgbakwunye C.1).

●Nnwale Mmiri: Nnwale iguzogide nrụgide site na nrụgide mmiri (Mgbakwunye C.2).

●Nnwale ikuku: Nchọpụta mmiri site na iji nrụgide ikuku/gas (Mgbakwunye C.3).

●Rịba ama: Nnwale ụdị mbụ na-amanye ECT; ụzọ ndị ọzọ bụ nhọrọ nke onye nrụpụta.

9. Nnwale:

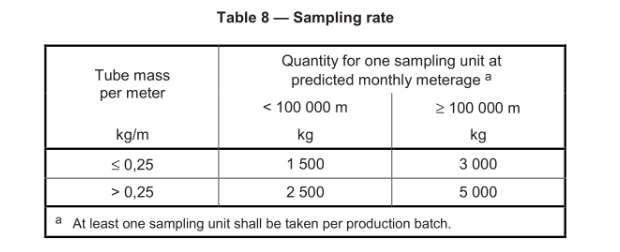

Maka ebumnuche nke ijide n'aka na mma dị n'oge mmepụta, ọnụọgụgụ nke nkeji nlele a ga-ewere n'usoro enweghị usoro ga-abụdịka Tebụl 8 si dị.

Ọnụego nlele ndị a ga-adị irè mgbe a na-anwale maka njikwa nha; a ga-eme njikwa nke ihe ndị ọzọ a chọrọ n'aka na nkeji nlele nke abụọ ọ bụla.

Enwere ike iji nsonaazụ ya mee ihe site na nyocha emere n'oge mbụ nke imepụta ngwaahịa ahụ, dịka ọmụmaatụ n'oge nrụpụta ma ọ bụ billets n'ime ọkwa, ma ọ bụrụ na edobere njirimara ngwaahịa ahụ na ma ọ bụrụ na sistemụ njikwa mma nke onye nrụpụta ahụ kwekọrọ na ihe achọrọ dị na EN lSO 9001.

10.Nkwakọ ngwaahịa

Iji hụ na ejigide na njem dị mma, a na-etinye ọkpọkọ ọla kọpa anyị n'ime ngwugwu ndị a:

●Mkpuchi Mgbochi Oxidation: A na-etinye ihe nchekwa n'elu ọkpọkọ ọla kọpa iji gbochie oxidation na mgbanwe agba n'oge nchekwa na njem.

●Mkpuchi njedebe: A na-etinye mkpuchi ígwè plastik ma ọ bụ nke na-anaghị emebi emebi n'elu nsọtụ ọkpọkọ iji gbochie mmetọ na mmebi igwe.

●Njikọ: A na-ejikọta tubes dị iche iche site na nkọwapụta ma jiri eriri plastik siri ike kechie ha nke ọma iji belata mmegharị n'oge njem.

●Kraịt Osisi: A na-etinye ọkpọkọ ndị a kpara akpa n'ime igbe osisi ndị na-anaghị eguzogide mmiri. A na-eji ụfụfụ mmiri ma ọ bụ ihe ndị na-eme ka mmiri ghara ịgwụcha ekpuchi igbe ndị ahụ iji gbochie mmebi mmiri ma na-agbaso ụkpụrụ ahụike mba ụwa nke ISPM 15.

●Mkpuchi siri ike: A na-eji eriri ígwè ma ọ bụ ihe njide siri ike mechie igbe ndị ahụ. Enwere ike iji ihe mkpuchi ndị ọzọ kpuchie ha maka igbochi ihu igwe.

●Ntinye akara: E ji dayameta mpụta nke ọkpọkọ ahụ (OD), ọkpụrụkpụ mgbidi (WT), ogologo, ọnọdụ (dịka ọmụmaatụ, dị nro, ọkara siri ike), nọmba ogbe mmepụta, na ụbọchị dee igbe ọ bụla iji hụ na enwere ike ịchọta ya nke ọma.

11.Njem na Njem Nlekọta

Womic Steel na-eme ka nnyefe nke ọkpọkọ ọla kọpa EN 1057 dị mma n'oge na n'enweghị nsogbu:

●Nbupu Oké Osimiri: Mbupu zuru ụwa ọnụ n'ime akpa nwere nchekwa kwesịrị ekwesị

●Ụgbọ okporo ígwè ma ọ bụ ụgbọ okporo ígwè: Nbupu a pụrụ ịtụkwasị obi n'ime obodo na mpaghara

●Njem Njem nke Ihu Igwe Na-achịkwa: Dị maka ngwa ndị dị nro

●Akwụkwọ zuru oke: E nyere akwụkwọ mbupu na mkpuchi

●Ọla Kọpa Dị Ọcha: Ogologo oge pụrụ iche na iguzogide nchara

●Mmepụta Nkịtị: Nkwenye siri ike maka arụmọrụ a pụrụ ịtụkwasị obi

●Ngwọta Pụrụ Iche: Ogologo, ihu, na mkpuchi ahaziri ahazi dị

●Nnwale zuru oke: Hụ na e mere ihe kwekọrọ na ụkpụrụ mba ụwa

●Nkesa zuru ụwa ọnụ: Nnyefe zuru ụwa ọnụ a pụrụ ịtụkwasị obi ma dị irè n'oge

12.Uru nke Ịhọrọ Womic Steel

- ●Ọla Kọpa Dị Ọcha: Ogologo oge pụrụ iche na iguzogide nchara

- ●Mmepụta Nkịtị: Nkwenye siri ike maka arụmọrụ a pụrụ ịtụkwasị obi

- ●Ngwọta Pụrụ Iche: Ogologo, ihu, na mkpuchi ahaziri ahazi dị

- ●Nnwale zuru oke: Hụ na e mere ihe kwekọrọ na ụkpụrụ mba ụwa

- ●Nkesa zuru ụwa ọnụ: Nnyefe zuru ụwa ọnụ a pụrụ ịtụkwasị obi ma dị irè n'oge

13.Ngwa

A na-eji ọkpọkọ ọla kọpa EN 1057 eme ihe n'ọtụtụ ebe:

- Sistemụ Plọmbing: Nkesa mmiri ọṅụṅụ dị nchebe ma dịkwa irè

- Nkesa Gas: Ọ dị mma maka ngwa gas eke na LPG

- Sistemụ Nkpo Ọkụ: Arụmọrụ dị irè na radiators na ikpo ọkụ n'okpuru ala

- Refrigeration na Ikuku: Ọkwa okpomọkụ dị elu maka sistemụ oyi

- Ọkpọkọ Gas Ahụike: A tụkwasịrị obi n'ụlọ ọgwụ maka oxygen na gas ahụike

Mmechi

Ọkpọkọ ọla kọpa EN 1057 nke Womic Steel na-enye mma, ike, na ntụkwasị obi dị elu maka ngwa plọmbing, gas, na ụlọ ọrụ mmepụta ihe. Nkwa anyị na-etinye n'ichepụta ihe ziri ezi, nnwale siri ike, na ngwọta ndị ahịa na-eme ka anyị bụrụ onye mmekọ a pụrụ ịtụkwasị obi na ụlọ ọrụ ahụ.

Họrọ Womic Steel Group dịka onye mmekọ gị a pụrụ ịtụkwasị obi maka ezigbo mmaỌkpọkọ ọla kọpa&Ngwakọta na arụmọrụ nnyefe a na-apụghị imeri emeri. Nnọọ na ajụjụ!

Weebụsaịtị: www.womicsteel.com

ozi-e: sales@womicsteel.com

Ekwentị/WhatsApp/WeChat: Victor: +86-15575100681 ma ọ bụ Jack: +86-18390957568

Oge ozi: Maachị-10-2025