Ọla kọpa Womic, nkewa nkeWomic Steel, bụ ọkachamara na-emepụta ihe na onye na-eweta ngwaahịa zuru ụwa ọnụọkpọkọ ọla kọpa nke na-enweghị oxygen, na-enye ọkwa kachasị eluC10100 (OFE)ọkpọkọ ọla kọpa nwere ịdị ọcha a na-ekwe nkwa, ike eletrik, na arụmọrụ igwe. Mmepụta anyị kwekọrọ kpọmkwem naASTM B188naB601, na-ahụ na ọkpọkọ ọ bụla na-emezu ụkpụrụ mba ụwa maka ojiji ụlọ ọrụ mmepụta ihe dị elu.

Nwere ikike kachasị elu n'ụlọ ọrụ iji chịkwaa ọkwa oxygen nadị ala dị ka 5 ppm, na teknụzụ nchacha dị elu iji belata ihe ruru unyi niile n'okpuru 40 ppm, Womic Copper bụ onye nrụpụta gị maka ọkpọkọ ọla kọpa ziri ezi naebe nchekwa ọkụ eletrik, ngwa vacuum, ngwa eletrọniki, na sistemụ ụlọ nhicha.

1. Nchịkọta Ngwaahịa - C10100 Enweghị Oxygen Copper

Nọmba UN: C10100

Aha ya: OFE Copper (Ọla kọpa eletrọniki na-enweghị oxygen)

Ịdị ọcha: ≥ 99.99% Cu

Ọdịnaya Oxygen: ≤ 5 ppm (Nwa nwanyị nwere ike ijikwa n'etiti 3-5 ppm)

Ọgbakọ eletriki: ≥ 101% IACS

Ụkpụrụ:

●ASTM B188 – Tube ọla kọpa na-enweghị ntụpọ maka ntụ oyi na friji

●ASTM B68 / B75 – Tube ọla kọpa na-enweghị ntụpọ maka Injinịa Izugbe

●ASTM B280 – Ọkwa friji

●EN 12735-1 – Tubọọlụ ọla kọpa maka ntụ oyi na friji

● GB/T 1527 – Tubes ọla kọpa na-enweghị ntụpọ

● JIS H3300 – Ọkọlọtọ Japan maka Tubes Alloy Copper na Copper

Ọkpọkọ ọla kọpa Womic C10100 enweghị oxygen, ọ naghị ekwe ka ikuku gbaa, ọ na-enyekwa ike kachasị, iguzogide nchara, na ike ịrụ ọrụ, nke na-eme ka ọ dị mma maka sistemụ eletriki na okpomọkụ dị elu.

Nkwenye Akụkụ:

Nkwụsi Ike Nkwụsi Ike: ≤ 13 mm n'ogologo zuru oke

Ogologo Ntachi Obi: ± 13 mm

Ọnọdụ Elu: Dị ọcha ma ghara inwe ntụpọ ọ bụla ma ọ bụ ntụpọ elu nke nwere ike igbochi ojiji ebumnuche.

2. Ihe mejupụtara kemịkalụ - Ọla kọpa OFE dị ọcha nke ukwuu (C10100)

Womic Copper na-eme ka ọ dị mma na ọkpọkọ ọla kọpa C10100 ọ bụla gafere99.99% ịdị ọcha ọla kọpa, naA na-achịkwa oke ikuku oxygen na ≤ 0.0005% (5 ppm)Nkọwapụta ihe na-adịghị ọcha zuru oke bụ dịka ndị a:

| Ihe | PPM kachasị elu | Ihe | PPM kachasị elu |

| Antimony (Sb) | 4 | Lead (Pb) | 5 |

| Arsenic (Dịka) | 5 | Manganese (Mn) | 0.5 |

| Bismuth (Bi) | 1 | Nickel (Ni) | 10 |

| Cadmium (Cd) | 1 | Fọshọrọs (P) | 3 |

| Ígwè (Fe) | 10 | Seleniọm (Se) | 3 |

| Ọlaọcha (Ag) | 25 | Sọlfọ (S) | 15 |

| Tellurium (Te) | 2 | Tin (Sn) | 2 |

| Zinc (Zn) | 1 | Oxygen (O) | 0.0005 |

Oke adịghị ọcha zuru oke:

Antimony + Selenium + Arsenic + Tellurium + Bismuth + Tin + Manganese ................. Oke 40 ppm

Ọdịnaya ọla kọpa= 100% – Ihe ruru unyi niile. Ihe ruru unyi niile bụ mkpokọta ọlaọcha, sọlfọ, lead, tin, bismuth, arsenic, antimony, iron, nickel, mercury, zinc, phosphorus, selenium, tellurium, manganese, cadmium na oxygen.

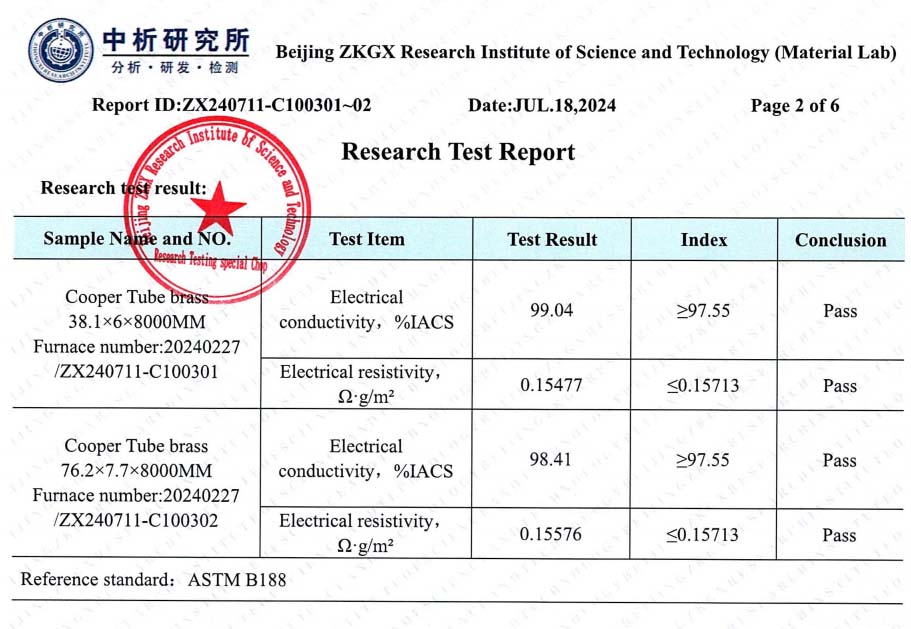

3. Njirimara eletriki na igwe

A na-emepụta ọkpọkọ ọla kọpa C10100 anyị nke na-enweghị oxygen maka ike na njikwa kacha mma, yana arụmọrụ na-aga n'ihu n'ofe otu mmepụta.

| Akụ na ụba | Uru nkịtị |

| Ọgbakọ eletriki | ≥IACS 101% |

| Nguzogide eletriki (20°C) | ≤0.15713 Ω·g/m2 |

| Ọgbakọ okpomọkụ | ≥398 W/m·K |

| Ike nrụgide (H80 temper) | ≥245 MPa |

| Ike Mwepụta | ≥205 MPa |

| Ogologo (karịa 5D) | ≥5% |

| Ike siri ike (Brinell HBW) | Nkeji80 |

| Nha ọka (kwa ASTM E112) | Mkpụrụ ọka mara mma otu |

4. Ngwa nke C10100 Copper Tube

Ọkpọkọ ọla kọpa anyị nke na-enweghị oxygen dị mma maka gburugburu dị mkpa nke chọrọ ịdị ọcha dị elu, ikike eletriki kwụsiri ike, na iguzosi ike n'ezi ihe n'elu:

●Nnyefe Ike na Ọdụ Ụgbọala - Ọdụ ụgbọ ala ọla kọpa, ndị na-eduzi ya na ọdụ ụgbọ ala 110–500 kV

● Sistemụ Vacuum na Ngwa ngwa - ọla kọpa nke dakọtara na UHV, nke enweghị hydrogen maka physics ihe ndị dị ndụ

●Egwuregwu Eletrọniki na Ndị Agha – Sistemụ waya, nduzi ebili mmiri, oghere RF

●Cryogenics na onyonyo ahụike - nnyefe helium/nitrogen mmiri mmiri, ihe mejupụtara igwe MRI

● HVAC na Refrigeration - Tubọọlụ ndị na-enweghị ntụpọ, dị ọcha nke ukwuu maka sistemụ oyi ziri ezi

●Ngwa Semiconductor na Cleanroom – Paịpụ enweghị oxygen maka eriri gas na oyi

● Sistemụ Inverters na Batrị nke Anyanwụ - Ogwe bọs na njikọ dị elu

5. Njikwa Ogo na Nnwale Ụlọ Nyocha

Iji mezuo ụkpụrụ kachasị elu, Womic Copper na-ejikọta usoro nyocha zuru oke n'ime ụlọ, gụnyere:

Ngwa dị elu:

● Ihe nyocha oxygen (dabere na IR) - Na-achọpụta oxygen ruo ihe karịrị 3 ppm

● Igwe nlele ihe eji eme ka ihe dị n'ime Atomic Absorption - Na-atụ ihe ruru unyi nke ígwè

● Ndị nnwale Eddy Ugbu a - Nchọpụta ntụpọ na-anaghị emebi emebi

● Ndị na-anwale Brinell na Vickers Hardness Tests - Na-eme ka njirimara igwe na-agbanwe agbanwe

● Nyocha nke Microstructure (SEM + Metallography) - Nyocha nke ọka na itinye ya

● Igwe Nnwale Nrụgide zuru ụwa ọnụ - Nkwenye ike mekaniki zuru oke

● Nnwale Nduzi (Nhazi IACS) - Na-enyocha arụmọrụ ≥101%

Nnwale Ndị Ọzọ:

Anyị na-akwado nyocha zuru oke site n'aka ndị otu mba ụwa dịka SGS, TÜV, BV, na DNV, yana akụkọ zuru ezu ewepụtara tupu e nye ha ya.

6. Nkwakọ ngwaahịa, Mbupu na Ọrụ Ụlọ Ọrụ

Womic Copper na-enye nkwakọ ngwaahịa dị mma, nke a na-ebupụ n'ọkwa mbupu iji chebe ịdị mma nke ngwaahịa n'oge mbupu n'ime obodo ma ọ bụ nke mba ofesi.

Atụmatụ Nkwakọ ngwaahịa:

● Mkpuchi njedebe plastik + ihe mkpuchi poly nke ọ bụla

●Akpa PE e ji vacuum mechie iji gbochie oxidation

● Igbe osisi e ji ígwè mee ka ọ dị ọkụ

● Tubọọlụ ọ bụla e ji nọmba okpomọkụ, nọmba ebe a na-edebe ihe, na nkọwapụta akara ya

Njem:

●Dị na FCL, LCL, na ibu ụgbọelu

●Ọrụ nhazi gụnyere CIF, FOB, DDP, na EXW

● Ibu ibu siri ike + ịpịa ihe maka mbupu dị anya

●Akwụkwọ ndị a kwadebere maka ụlọ ọrụ kọstọm, ọdụ ụgbọ mmiri, na ụlọ ọrụ ndị ọzọ

7. Gịnị mere ị ga-eji họrọ Womic Copper

●Njikwa Oxygen Dị Ala nke Ukwuu - Ọkwa oxygen 3–5 ppm, nke kachasị elu n'ime ụlọ ọrụ mmepụta ihe

●Mmepụta Dị Elu Na-enweghị Ntụpọ - eserese zuru oke na-ekpo ọkụ + oyi, annealing, okpomọkụ H80

● Sistemụ Nlele QC 100% - Nlele dijitalụ site na njedebe ruo na njedebe

●Ahụmịhe Ọrụ N'ụwa Nile - Enyere sistemụ nchekwa 500kV na Eshia na Yuropu

●Nnọọ na Nnyocha Ụlọ Ọrụ - Nnyocha ebe a, mmepụta doro anya

●Nchekwa na Nhazi zuru ụwa ọnụ - Nnyefe n'oge yana akwụkwọ zuru oke

Oge ozi: Eprel-05-2025