Nkọwa Ngwaahịa

A na-ejikarị mkpuchi na ọkpọkọ eme ihe maka mmepụta mmanụ na gas. Ihe mkpuchi na ọkpọkọ bụ ihe dị mkpa n'ụlọ ọrụ mmanụ na gas nke e ji ewepụta ma bufee hydrocarbons (mmanụ na gas) site na ọdọ mmiri dị n'okpuru ala ruo n'elu ala. Ha na-arụ ọrụ dị mkpa n'ịhụ na ọrụ ịgbapụta ihe na mmepụta na nchekwa, iguzosi ike n'ezi ihe, na arụmọrụ.

Tubing bụ ụdị paịpụ e ji ebufe mmanụ na gas sitere n'oyi akwa mmanụ ma ọ bụ oyi akwa gas gaa n'ala mgbe a gwuchara ya. Tubing can na-enye ohere ka nrụgide e nwetara n'oge a na-ewepụta ya pụta. Tubing na-emepụta otu ụzọ ahụ e si emepụta casing, mana usoro a na-akpọ "ihe na-akpasu iwe" dịkwa mkpa iji mee ka paịpụ ọkpọkọ ahụ sie ike.

A na-eji mkpuchi ahụ echebe olulu ndị e gwuru n'ime ala maka mmanụ. A na-eji ya dịka ọkpọkọ olulu mmanụ eme ihe, ọ na-enyekwa aka na nrụgide nrụgide axial, yabụ a chọrọ ígwè siri ike dị elu. Ihe mkpuchi OCTG bụ nnukwu ọkpọkọ dayameta nke e tinyere simenti n'ime olulu mmiri ahụ.

Nkọwapụta

| API 5L: GR.B, X42, X46, X52, X56, X60, X65, X70, X80 |

| API 5CT: J55, K55, N80, L80, P110 |

| API 5D: E75, X95, G105, S135 |

| EN10210: S235JRH, S275J0H, S275J2H, S355J0H, S355J2H, S355K2H |

| ASTM A106: GR.A, GR.B, GR.C |

| ASTM A53/A53M: GR.A, GR.B |

| ASTM A335: P1, P2, 95, P9, P11P22, P23, P91, P92, P122 |

| ASTM A333: Gr.1, Gr.3, Gr.4, Gr.6, Gr.7, Gr.8, Gr.9.Gr.10, Gr.11 |

| DIN 2391: St30Al, St30Si, St35, St45, St52 |

| DIN EN 10216-1: P195TR1, P195TR2, P235TR1, P235TR2, P265TR1, P265TR2 |

| JIS G3454: STPG 370, STPG 410 |

| JIS G3456: STPT 370, STPT 410, STPT 480 |

| GB/T 8163: 10#, 20#, Q345 |

| GB/T 8162: 10#, 20#, 35#, 45#, Q345 |

Ndepụta ihe mkpuchi ígwè ISO/API

| Aha ndị e ji mee ihea | N'èzí dayameta D mm | Aha aha ahịrị kwụ ọtọ ukab, c Usoro na Usoro kg/m | Mgbidi ọkpụrụkpụ t mm | Ụdị njedebe njedebe | ||||||||

| 1 | 2 | H40 | J55 K55 | M65 | L80 C95 | N80 Ụdị nke 1, Q | C90 T95 | P110 | Q125 | |||

| 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 | 13 |

| 4-1/2 4-1/2 4-1/2 4-1/2 4-1/2 | 9.50 10.50 11.60 13.50 15.10 | 114,30 114,30 114,30 114,30 114,30 | 14,14 15,63 17,26 20,09 22,47 | 5,21 5,69 6,35 7,37 8,56 | PS — — — — | PS PSB PSLB — — | PS PSB PLB PLB — | — — PLB PLB — | — — PLB PLB — | — — PLB PLB — | — — PLB PLB PLB | — — — — PLB |

| 5 5 5 5 5 5 5 | 11.50 13.00 15.00 18.00 21.40 23.20 24.10 | 127,00 127,00 127,00 127,00 127,00 127,00 127,00 | 17,11 19,35 22,32 26,79 31,85 34,53 35,86 | 5,59 6,43 7,52 9,19 11,10 12,14 12,70 | — — — — — — — | PS PSLB PSLBE — — — — | PS PSLB PLB PLB PLB — — | — — PLBE PLBE PLB PLB PLB | — — PLBE PLBE PLB PLB PLB | — — PLBE PLBE PLB PLB PLB | — — PLBE PLBE PLB PLB PLB | — — — PLBE PLB PLB PLB |

| 5-1/2 5-1/2 5-1/2 5-1/2 5-1/2 5-1/2 5-1/2 5-1/2 5-1/2 5-1/2 5-1/2 5-1/2 | 14.00 15.50 17.00 20.00 23.00 26.80 29.70 32.60 35.30 38.00 40.50 43.10 | 139,70 139,70 139,70 139,70 139,70 139,70 139,70 139,70 139,70 139,70 139,70 139,70 | 20,83 23,07 25,30 29,76 34,23 39,88 44,20 48,51 52,53 56,55 60,27 64,14 | 6,20 6,98 7,72 9,17 10,54 12,70 14,27 15,88 17,45 19,05 20,62 22,22 | PS | PS PSLBE PSLBE | PS PSLB PLB PLB PLB | — — PLBE PLBE PLBE — — — — — — — | PLBE PLBE PLBE | PLBE PLBE PLBE P P P P P P P | PLBE PLBE PLBE | — — — — PLBE — — — — — — |

| 6-5/8 6-5/8 6-5/8 6-5/8 | 20.00 24.00 28.00 32.00 | 168,28 168,28 168,28 168,28 | 29,76 35,72 41,67 47,62 | 7,32 8,94 10,59 12,06 | PS — — | PSLB PSLBE — | PSLB PLB PLB — | — PLBE PLBE PLBE | — PLBE PLBE PLBE | — PLBE PLBE PLBE | — PLBE PLBE PLBE | — — PLBE |

| 7 7 7 7 7 7 7 7 7 7 7 7 7 | 17.00 20.00 23.00 26.00 29.00 32.00 35.00 38.00 42.70 46.40 50.10 53.60 57.10 | 177,80 177,80 177,80 177,80 177,80 177,80 177,80 177,80 177,80 177,80 177,80 177,80 177,80 | 25,30 29,76 34,23 38,69 43,16 47,62 52,09 56,55 63,54 69,05 74,56 79,77 84,97 | 5,87 6,91 8,05 9,19 10,36 11,51 12,65 13,72 15,88 17,45 19,05 20,62 22,22 | PS PS — — — — — — — — — — — | — PS PSLBE PSLBE — — — — — — — — — | — PS PLB PLB PLB PLB — — — — — — — | — — PLBE PLBE PLBE PLBE PLBE PLBE — — — — — | — — PLBE PLBE PLBE PLBE PLBE PLBE — — — — — | — — PLBE PLBE PLBE PLBE PLBE PLBE P P P P P | — — — PLBE PLBE PLBE PLBE PLBE — — — — — | — — — — — — PLBE PLBE — — — — — |

| Lee ihe ndetu dị na njedebe nke tebụl. | ||||||||||||

| Aha ndị e ji mee ihea | N'èzí dayameta D mm | Aha aha ahịrị kwụ ọtọ ukab, c Usoro na Usoro kg/m | Mgbidi ọkpụrụkpụ t mm | Ụdị njedebe njedebe | ||||||||

| 1 | 2 | H40 | J55 K55 | M65 | L80 C95 | N80 Ụdị nke 1, Q | C90 T95 | P110 | Q125 | |||

| 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 | 13 |

| 7-5/8 7-5/8 7-5/8 7-5/8 7-5/8 7-5/8 7-5/8 7-5/8 7-5/8 7-5/8 | 24.00 26.40 29.70 33.70 39.00 42.80 45.30 47.10 51.20 55.30 | 193,68 193,68 193,68 193,68 193,68 193,68 193,68 193,68 193,68 193,68 | 35,72 39,29 44,20 50,15 58,04 63,69 67,41 70,09 76,19 82,30 | 7,62 8,33 9,52 10,92 12,70 14,27 15,11 15,88 17,45 19,05 | PS | PSLBE | PSLB PLB PLB | PLBE PLBE PLBE PLBE PLB PLB PLB | PLBE PLBE PLBE PLBE PLB PLB PLB | PLBE PLBE PLBE PLBE PLB PLB PLB P P | PLBE PLBE PLBE PLB PLB PLB | PLBE PLB PLB PLB |

| 7-3/4 | 46.10 | 19,685 | 6,860 | 1,511 | — | — | — | P | P | P | P | P |

| 8-5/8 8-5/8 8-5/8 8-5/8 8-5/8 8-5/8 8-5/8 | 24.00 28.00 32.00 36.00 40.00 44.00 49.00 | 219,08 219,08 219,08 219,08 219,08 219,08 219,08 | 35,72 41,67 47,62 53,57 59,53 65,48 72,92 | 6,71 7,72 8,94 10,16 11,43 12,70 14,15 | PS PS — — — — | PS — PSLBE PSLBE — — — | PS PS PSLB PSLB PLB — — | — — — PLBE PLBE PLBE PLBE | — — — PLBE PLBE PLBE PLBE | — — — PLBE PLBE PLBE PLBE | — — — — PLBE PLBE PLBE | — — — — — — PLBE |

| 9-5/8 9-5/8 9-5/8 9-5/8 9-5/8 9-5/8 9-5/8 9-5/8 9-5/8 9-5/8 9-5/8 | 32.30 36.00 40.00 43.50 47.00 53.50 58.40 59.40 64.90 70.30 75.60 | 244,48 244,48 244,48 244,48 244,48 244,48 244,48 244,48 244,48 244,48 244,48 | 48,07 53,57 59,53 64,73 69,94 79,62 86,91 88,40 96,58 104,62 112,50 | 7,92 8,94 10,03 11,05 11,99 13,84 15,11 15,47 17,07 18,64 20,24 | PS PS — — — — — — — — — | — PSLB PSLBE — — — — — — — — | — PSLB PSLB PLB PLB — — — — — — | — — PLBE PLBE PLBE PLBE PLB — — — — | — — PLBE PLBE PLBE PLBE PLB — — — — | — — PLBE PLBE PLBE PLBE PLB P P P P | — — — PLBE PLBE PLBE PLB — — — — | — — — — PLBE PLBE PLB — — — — |

| 10-3/4 10-3/4 10-3/4 10-3/4 10-3/4 10-3/4 10-3/4 10-3/4 10-3/4 10-3/4 | 32.75 40.50 45.50 51.00 55.50 60.70 65.70 73.20 79.20 85.30 | 273,05 273,05 273,05 273,05 273,05 273,05 273,05 273,05 273,05 273,05 | 48,74 60,27 67,71 75,90 82,59 90,33 97,77 108,93 117,86 126,94 | 7,09 8,89 10,16 11,43 12,57 13,84 15,11 17,07 18,64 20,24 | PS PS | PSB PSBE PSBE | PSB PSB PSB PSB | PSBE PSBE | PSBE PSBE | PSBE PSBE PSBE PSB P P P | PSBE PSBE PSBE PSB | PSBE PSB |

| 11-3/4 11-3/4 11-3/4 11-3/4 11-3/4 11-3/4 | 42.00 47.00 54.00 60.00 65.00 71.00 | 298,45 298,45 298,45 298,45 298,45 298,45 | 62,50 69,94 80,36 89,29 96,73 105,66 | 8,46 9,53 11,05 12,42 13,56 14,78 | PS — — — | PSB PSB PSB — — | PSB PSB PSB — — | — — PSB P P | — — PSB P P | — — PSB P P | — — PSB P P | — — PSB P P |

| 13-3/8 13-3/8 13-3/8 13-3/8 13-3/8 | 48.00 54.50 61.00 68.00 72.00 | 339,72 339,72 339,72 339,72 339,72 | 71,43 81,10 90,78 101,19 107,15 | 8,38 9,65 10,92 12,19 13,06 | PS — — — — | — PSB PSB PSB — | — PSB PSB PSB — | — — — PSB PSB | — — — PSB PSB | — — — PSB PSB | — — — PSB PSB | — — — — PSB |

| Lee ihe ndetu dị na njedebe nke tebụl. | ||||||||||||

| Aha ndị e ji mee ihea | N'èzí dayameta D mm | Aha aha ahịrị kwụ ọtọ ukab, c Usoro na Usoro kg/m | Mgbidi ọkpụrụkpụ t mm | Ụdị njedebe njedebe | ||||||||

| 1 | 2 | H40 | J55 K55 | M65 | L80 C95 | N80 Ụdị nke 1, Q | C90 T95 | P110 | Q125 | |||

| 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 | 13 |

| 16 16 16 16 | 65.00 75.00 84.00 109.00 | 406,40 406,40 406,40 406,40 | 96,73 111,61 125,01 162,21 | 9,53 11,13 12,57 16,66 | PS | PSB PSB P | PSB PSB | P | P | P | P | |

| 18-5/8 | 87.50 | 47,308 | 13,021 | 1,105 | PS | PSB | PSB | — | — | — | — | — |

| 20 20 20 | 94.00 106.50 133.00 | 508,00 508,00 508,00 | 139,89 158,49 197,93 | 11,13 12,70 16,13 | PSL — — | PSLB PSLB PSLB | PSLB PSLB — | — — — | — — — | — — — | — — — | — — — |

| P = Ngwụcha dị larịị, S = Eriri dị mkpụmkpụ, L = Eriri dị ogologo gburugburu, B = Eriri Buttress, E = Ahịrị dị oke elu. | ||||||||||||

| ♦ Akara ngosi bụ maka ozi na enyemaka n'ịtụ ihe. ♦ A na-egosi oke ahịrị aha, nke e ji eriri mee ma jikọta (kọl. 2) maka ozi naanị. ♦ Njupụta nke ígwè martensitic chromium (ụdị L80 9Cr na 13Cr) dị iche na ígwè carbon. Ya mere, oke egosiri ezighi ezi maka ígwè martensitic chromium. Enwere ike iji ihe nhazi oke nke 0,989 mee ihe. | ||||||||||||

| Aha ndị e ji mee ihe | Dayameta mpụta D mm | Ahịrị kwụ ọtọ uka kg/m | Ọkpụrụkpụ mgbidi t mm | |

| 1 | 2 | |||

| 1 | 2 | 3 | 4 | 5 |

| 3-1/2 4 4-1/2 5 5-1/2 6-5/8 | 9.92 11.35 13.05 17.95 19.83 27.66 | 88,90 101,60 114,30 127,00 139,70 168,28 | 14,76 16,89 19,42 26,71 29,51 41,18 | 7,34 7,26 7,37 9,19 9,17 10,59 |

Ndepụta ọkpọkọ ígwè ISO/API

| Aha ndị e ji mee ihe | N'èzí dayameta D mm | Ahịrị aha ọtụtụ mmadụa, b | Mgbidi oké- ness t mm | Ụdị njedebe njedebec | |||||||||||

| Ndị na-abụghị bilie dị njikere Usoro na Usoro kg/m | Mgbakwunye. bilie dị njikere Usoro na Usoro kg/m | Integ. nkwonkwo kg/m | |||||||||||||

| 1 | 2 | ||||||||||||||

| NU Usoro na Usoro | EU Usoro na Usoro | IJ | H40 | J55 | L80 | N80 Ụdị nke 1, Q | C90 | T95 | P110 | ||||||

| 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 | 13 | 14 | 15 | 16 |

| 1,900 1,900 1,900 1,900 1,900 | 2.40 2.75 3.65 4.42 5.15 | — 2.90 3.73 — — | 2.40 2.76 — — — | 48,26 48,26 48,26 48,26 48,26 | — 4,09 5,43 6,58 7,66 | — 4,32 5,55 — — | 3,57 4,11 — — — | 3,18 3,68 5,08 6,35 7,62 | PI PNUI PU — — | PI PNUI PU — — | — PNUI PU P P | — PNUI PU — — | — PNUI PU P P | — PNUI PU P P | PU — — |

| 2.063 2.063 | 3.24 4.50 | — — | 3.25 — | 52,40 52,40 | — — | — — | 4,84 — | 3,96 5,72 | PI P | PI P | PI P | PI P | PI P | PI P | P |

| 2-3/8 2-3/8 2-3/8 2-3/8 2-3/8 | 4.00 4.60 5.80 6.60 7.35 | 4.70 5.95 7.45 | 60,32 60,32 60,32 60,32 60,32 | 5,95 6,85 8,63 9,82 10,94 | 6,99 8,85 11,09 | 4,24 4,83 6,45 7,49 8,53 | PN PNU | PN PNU | PN PNU PNU P PU | PN PNU PNU — — | PN PNU PNU P PU | PN PNU PNU P PU | PNU PNU | ||

| 2-7/8 2-7/8 2-7/8 2-7/8 | 6.40 7.80 8.60 9.35 | 6.50 7.90 8.70 9.45 | — — — | 73,02 73,02 73,02 73,02 | 9,52 11,61 12,80 13,91 | 9,67 11,76 12,95 14,06 | — — — | 5,51 7,01 7,82 8,64 | PNU — — | PNU — — | PNU PNU PNU PU | PNU PNU PNU — | PNU PNU PNU PU | PNU PNU PNU PU | PNU PNU PNU — |

| 2-7/8 2-7/8 | 10.50 11.50 | — | — | 73,02 73,02 | 15,63 17,11 | — | — | 9,96 11,18 | — | — | P P | — | P P | P P | — |

| 3-1/2 3-1/2 3-1/2 3-1/2 3-1/2 3-1/2 3-1/2 | 7.70 9.20 10.20 12.70 14.30 15.50 17.00 | — 9.30 — 12.95 — — — | — — — — — — — | 88,90 88,90 88,90 88,90 88,90 88,90 88,90 | 11,46 13,69 15,18 18,90 21,28 23,07 25,30 | — 13,84 — 19,27 — — — | — — — — — — — | 5,49 6,45 7,34 9,52 10,92 12,09 13,46 | PN PNU PN — — — — | PN PNU PN — — — — | PN PNU PN PNU P P P | PN PNU PN PNU — — — | PN PNU PN PNU P P P | PN PNU PN PNU P P P | — PNU — PNU — — — |

| 4 4 4 4 4 4 | 9.50 10.70 13.20 16.10 18.90 22.20 | — 11.00 — — — — | — — — — — — | 101,60 101,60 101,60 101,60 101,60 101,60 | 14,14 — 19,64 23,96 28,13 33,04 | — 16,37 — — — — | — — — — — — | 5,74 6,65 8,38 10,54 12,70 15,49 | PN PU — — — — | PN PU — — — — | PN PU P P P P | PN PU — — — — | PN PU P P P P | PN PU P P P P | — — — — — — |

| 4-1/2 4-1/2 4-1/2 4-1/2 4-1/2 4-1/2 4-1/2 | 12.60 15.20 17.00 18.90 21.50 23.70 26.10 | 12.75 | 114,30 114,30 114,30 114,30 114,30 114,30 114,30 | 18,75 22,62 25,30 28,13 32,00 35,27 38,84 | 18,97 | 6,88 8,56 9,65 10,92 12,70 14,22 16,00 | PNU | PNU | PNU P P P P P P | PNU — — — — — — | PNU P P P P P P | PNU P P P P P P | |||

| P = Ngwụcha dị larịị, N = Eriri na-anaghị agbawa agbawa ma jikọta, U = Eriri na-agbawa agbawa mpụta, I = Nkwonkwo Integral. | |||||||||||||||

| ♦ E gosiri oke ahịrị, eriri na njikọ (col. 2, 3, 4) maka ozi naanị. ♦ Njupụta nke ígwè martensitic chromium (ụdị L80 9Cr na 13Cr) dị iche na ígwè carbon. Ya mere, oke egosiri ezighi ezi maka ígwè martensitic chromium. Enwere ike iji ihe nhazi oke nke 0,989 mee ihe. ♦ A na-enweta ọkpọkọ na-anaghị agbawa agbawa site na njikọ nkịtị ma ọ bụ njikọ bevel pụrụ iche. A na-enweta ọkpọkọ na-agbawa agbawa site na njikọ nkịtị, nke pụrụ iche, ma ọ bụ nke pụrụ iche. | |||||||||||||||

Ọkọlọtọ na ọkwa

Kịsị na ọkpọkọ. Ọkwa ọkọlọtọ:

API 5CT J55,K55,L80,N80,P110,C90,T95,H40

Ngwụcha nke ọkpọkọ API 5CT na ọkpọkọ ọkpọkọ:

(STC)Mkpụchi eriri gbara okirikiri dị mkpụmkpụ

(LC) Ihe mkpuchi eriri gburugburu ogologo

(BC) Ihe mkpuchi eriri buttress

Ihe mkpuchi dị oke elu (XC)

(NU)Ọkpọkọ mmiri na-anaghị agbawa agbawa

(EU)Tubụ mpụta nke na-agbawa agbawa

(IJ) Ọkpọkọ njikọ integral

E kwesịrị ibuga ihe mkpuchi na ọkpọkọ ahụ dịka njikọ dị n'elu na ọkọlọtọ API5CT / API si dị.

Njikwa Ogo

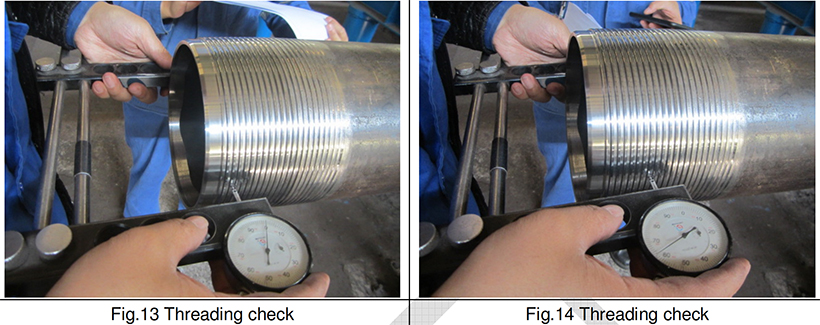

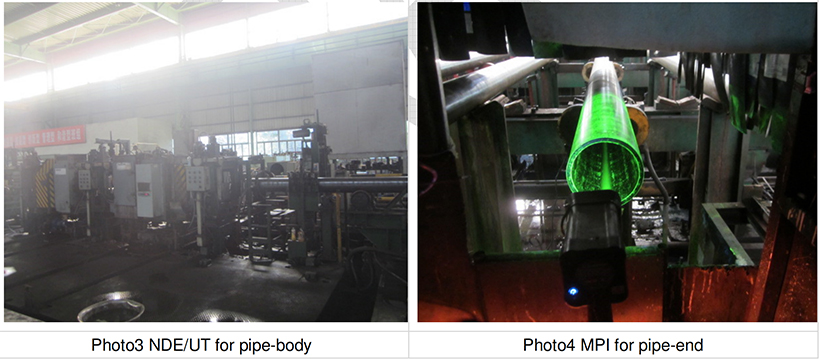

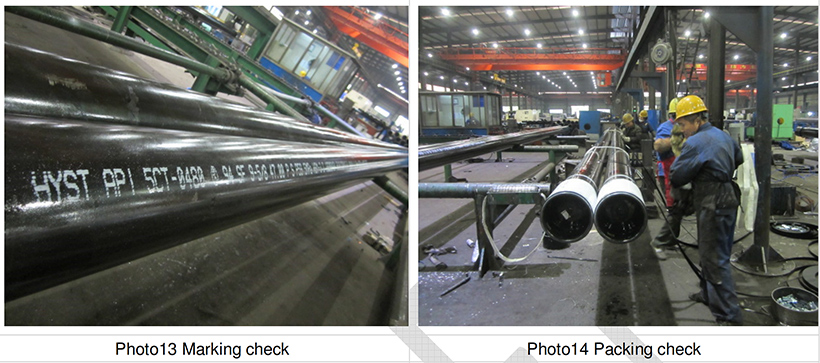

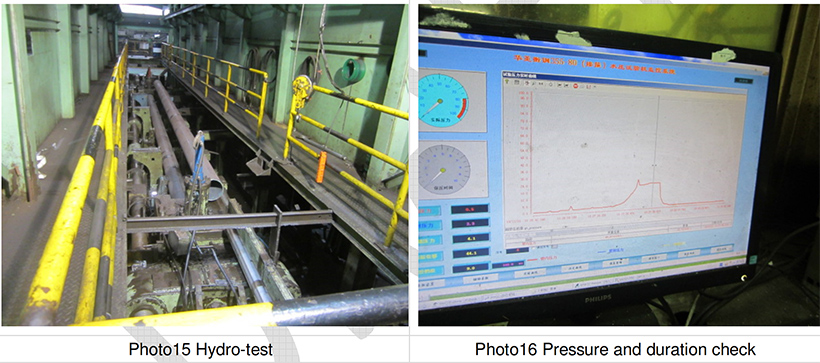

Nnyocha Ihe Ndị Dị n'ime, Nnyocha Kemịkalụ, Nnwale Mekanik, Nnyocha Anya, Nnwale Nrụgide, Nlele Nha, Nnwale Gbagọrọ Agbagọ, Nnwale Flattening, Nnwale Mmetụta, Nnwale DWT, Nnwale NDT, Nnwale Hydrostatic, Nnwale Ike....

Akara, Agba agba tupu ebuga ya.

Nkwakọ ngwaahịa na Mbupu

Usoro nkwakọ ngwaahịa maka paịpụ ígwè gụnyere ihicha, ịchịkọta, kechie, ijikọ, ịchekwa, itinye akara, itinye pallet (ọ bụrụ na ọ dị mkpa), itinye akpa, ịchekwa, ịkpuchi, ibuga, na iwepụ ihe. Ụdị paịpụ ígwè dị iche iche na ihe ndị e ji etinye ya na ụzọ nkwakọ ngwaahịa dị iche iche. Usoro a zuru oke na-eme ka a hụ na paịpụ ígwè na-ebuga ma rute ebe ha na-aga n'ọnọdụ kacha mma, dị njikere maka ojiji ha.

Ojiji na Ngwa

Paịpụ ígwè na-arụ ọrụ dị ka isi ihe dị mkpa nke injinịa ụlọ ọrụ mmepụta ihe na obodo nke oge a, na-akwado ọtụtụ ngwa ndị na-enyere aka na mmepe nke ọha mmadụ na akụnụba n'ụwa niile.

Paịpụ ígwè na ihe ndị e ji arụ ọrụ na Womic Steel, nke a na-ejikarị eme ihe maka mmanụ ala, gas, mmanụ ọkụ na mmiri, ọrụ owuwu na ụlọ dị n'ụsọ oké osimiri/n'ụsọ oké osimiri, ọrụ owuwu na ụlọ nke ọdụ ụgbọ mmiri, igwu mmiri, ọrụ owuwu ígwè, ọrụ owuwu mkpọ na akwa mmiri, yana ọkpọkọ ígwè ziri ezi maka mmepụta ihe eji ebufe ihe, wdg...